Imagine a machine. For decades, that word has conjured images of rigid metal, whirring gears, hydraulic pistons, and stiff, jerky movements. We think of assembly line arms or the metallic skeleton of the Terminator. These “hard” robots are excellent at precision and power, but they struggle with the chaotic, unstructured, and delicate reality of the natural world. They cannot squeeze through a crack in a wall, they might crush a ripe tomato if they try to pick it, and they are often dangerous to be around without safety cages.

Enter bio-inspired soft robotics.

This rapidly evolving field represents a fundamental shift in engineering philosophy. Instead of building robots that look like machines, engineers are building robots that look and behave like biological organisms. By mimicking the compliant bodies of octopuses, the peristaltic motion of worms, and the growing tips of vines, scientists are creating a new class of machines made from silicone, fabric, hydrogels, and fluids. These robots are safe to touch, adaptable to the unknown, and capable of movements that traditional robots simply cannot perform.

Key Takeaways

- Fundamental Shift: Soft robotics moves away from rigid links and joints to continuous, deformable bodies.

- Safety First: Because they are made of soft materials, these robots are inherently safer for human interaction.

- Biomimicry: The designs are directly stolen from nature’s playbook—mimicking muscles, tentacles, and skins.

- Versatility: They excel in handling fragile objects (food, tissues) and navigating unstructured environments (rubble, human bodies).

- Complex Control: Controlling a soft body is mathematically harder than a rigid one, requiring new approaches to sensing and AI.

Scope of This Guide

In this comprehensive guide, we will explore the world of bio-inspired soft robotics. We will cover:

- In Scope: Robotics built primarily from compliant materials (elastomers, fluids, fabrics), mechanisms inspired by biological movement (crawling, grasping, swimming), and applications in healthcare, industry, and exploration.

- Out of Scope: Traditional rigid humanoid robots, purely software-based AI (unless controlling a soft body), and biological enhancements to humans (cyborgs) that do not involve soft robotic principles.

What Is Bio-Inspired Soft Robotics?

To understand bio-inspired soft robotics, we must first understand the concept of “compliance.” In engineering, compliance is the inverse of stiffness. A steel beam has low compliance; a rubber band has high compliance. Traditional robotics relies on high stiffness to maintain accuracy. If you tell a robot arm to move to coordinate X,Y,Z, you want it to go exactly there, regardless of external forces.

Soft robotics flips this logic. It embraces compliance. These robots are designed to deform. When a soft robot hand grabs an object, it doesn’t calculate the exact geometry of the object; it simply wraps around it, conforming to the shape naturally, much like your own hand does when grasping a beanbag.

The Biological Connection

Nature rarely works in straight lines and rigid joints. Most biological organisms are soft, or at least have significant soft components.

- The Octopus: It has no bones, yet it can manipulate objects with incredible dexterity and apply significant force.

- The Elephant Trunk: A muscular hydrostat that can uproot a tree or pick up a peanut.

- The Earthworm: It moves by changing its shape, using waves of muscle contraction to push against the soil.

Bio-inspired soft robotics seeks to replicate these capabilities by using materials that match the “Young’s Modulus” (a measure of elasticity) of biological tissue. By using materials that feel like skin and muscle, we bridge the gap between the mechanical and the organic.

The Biological Muses: Who Are We Copying?

The diversity of the animal kingdom provides an endless catalog of engineering solutions that have been field-tested by evolution for millions of years. Here are the primary biological organisms currently inspiring soft robot design.

1. Cephalopods (Octopuses and Squid)

The octopus is perhaps the “poster child” of soft robotics. It represents the ultimate challenge: how to move and manipulate without a skeleton.

- Mechanism: Cephalopods use a structure called a “muscular hydrostat.” Because water is incompressible, when muscles squeeze one part of the tentacle, another part must expand or extend.

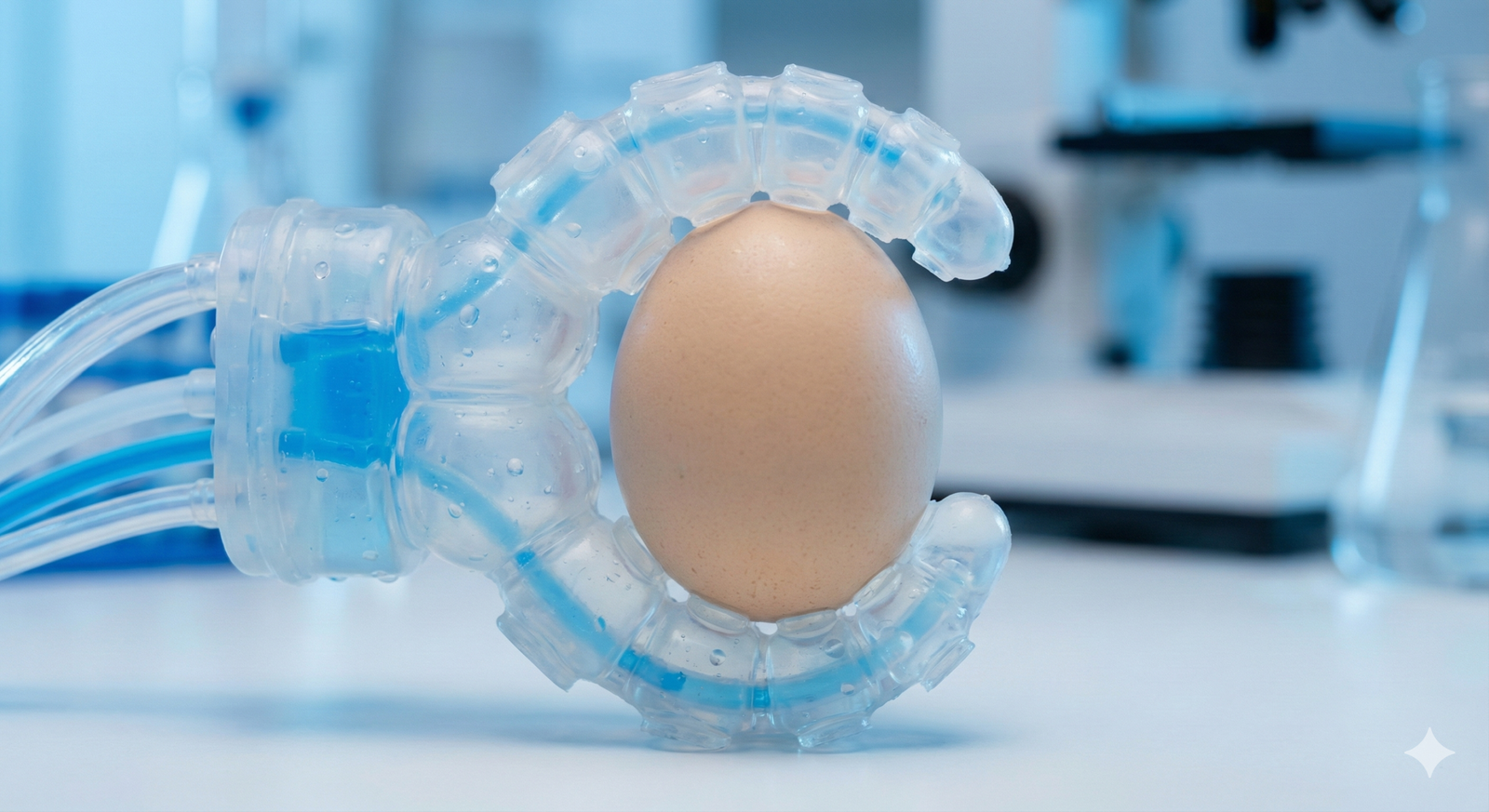

- Robotic Implementation: Engineers replicate this using pneumatic artificial muscles. By arranging air chambers in silicone arms, inflating specific chambers causes the arm to curl, extend, or twist.

- Utility: These robots are perfect for underwater exploration and delicate grasping. They can squeeze through tiny openings and then expand to perform a task.

2. Annelids and Larvae (Worms and Caterpillars)

Worms and caterpillars traverse rough terrain not by rolling or walking on stilts, but by deforming their bodies.

- Mechanism: They use “peristalsis”—a wave-like contraction that travels down the body. Some also use “hydrostatic skeletons,” using internal fluid pressure to maintain shape.

- Robotic Implementation: Soft crawling robots often use segments that can inflate and deflate in sequence. Mesh-like skins (braided fibers) constrain the inflation so that the robot lengthens rather than just ballooning out.

- Utility: These are ideal for pipe inspection, colonoscopy devices (moving gently through the intestine), and search-and-rescue operations in unstable rubble where a rigid robot might get stuck.

3. Plants (Vines and Roots)

We often forget that plants move, albeit slowly. However, some soft robots mimic the growth of plants rather than the muscular movement of animals.

- Mechanism: Vines navigate by growing at the tip, adding material to extend forward while the rest of the body remains stationary relative to the environment. This reduces friction.

- Robotic Implementation: “Everting” robots work like a sock being turned inside out. Pressurized air pushes inner material out through the tip, allowing the robot to “grow” forward.

- Utility: Because the body doesn’t slide against its surroundings, these robots can navigate extremely sticky surfaces, sharp turns, or delicate environments without causing friction damage. They are being tested for intubation and industrial repair.

4. Fish and Rays (Undulation)

Marine life offers efficient models for swimming using soft bodies.

- Mechanism: Rays use large, flexible pectoral fins to glide, while fish flex their bodies to generate thrust.

- Robotic Implementation: Soft robotic fish use dielectric elastomer actuators (DEAs) or fluidic chambers to flex a silicone tail.

- Utility: These robots are silent and camouflaged. They are used to observe marine life without disturbing it, as they look and move like real fish.

The “Flesh” of the Machine: Materials Science

You cannot build a soft robot out of steel and aluminum. The revolution in soft robotics is largely a revolution in materials science. The goal is to find materials that are durable, stretchable, and capable of surviving repeated cycles of deformation.

Elastomers and Silicones

The most common material in bio-inspired soft robotics is silicone rubber (polydimethylsiloxane or PDMS).

- Why use it? It is cheap, easy to cast in 3D-printed molds, biologically inert (safe for humans), and highly elastic.

- Trade-offs: Silicone can tear. If a soft robot under high pressure gets a pinhole leak, it can fail catastrophically (pop) or lose function. Recent research focuses on “self-healing” polymers that can chemically bond back together after being cut.

Hydrogels

Hydrogels are networks of polymer chains that are hydrophilic and contain a large amount of water. They are very similar to biological tissue.

- Why use it? They are nearly transparent and can be made biocompatible.

- Real-world example: Researchers have created hydrogel robots that can catch and release live fish without harming them. Because the refractive index of the hydrogel matches water, the robot is almost invisible underwater.

Smart Fabrics and Textiles

Textile-based soft robotics involves sewing air bladders or cables into fabric.

- Why use it? Fabric is lightweight, strong in tension (it doesn’t stretch infinitely like rubber), and wearable.

- Application: This is the primary material for “exosuits”—soft wearable robots that help stroke victims walk or assist soldiers in carrying heavy loads. Unlike rigid exoskeletons (think Iron Man), these look like hiking pants with specialized cabling.

Programmable Matter (Shape Memory)

Some materials change shape when exposed to heat or electricity.

- Shape Memory Alloys (SMAs): A wire made of Nitinol (nickel-titanium) remembers its shape. You can deform it, but if you heat it up (usually by running a current through it), it snaps back to its original shape. This acts like a slow, strong muscle.

Making it Move: Actuation Strategies

How do you move a robot that has no motor? In rigid robotics, movement is usually driven by electric motors (servos) at the joints. In soft robotics, the actuation is often distributed throughout the body.

1. Fluidic Elastomer Actuators (FEAs)

This is the most common method. It involves pumping a fluid (air or liquid) into chambers within the soft body.

- Pneumatic (Air): Fast, lightweight, and clean. However, air is compressible, which makes precise control “spongy” and difficult.

- Hydraulic (Water/Oil): Water is incompressible, offering much stronger force and precision. However, it is heavy and creates a mess if it leaks.

- Mechanism: By designing the chambers with asymmetric walls (e.g., one side is thicker than the other), inflating the chamber causes it to bend toward the thicker side. This creates curling motion.

2. Cable-Driven (Tendon) Actuation

This mimics the way our fingers work. High-strength cables (tendons) run through channels inside the soft body.

- How it works: An electric motor pulls the cable, causing the soft structure to buckle or bend.

- Pros/Cons: It is easier to control than pneumatics because we understand motor math very well. However, friction between the cable and the channel is a major issue.

3. Electroactive Polymers (EAPs)

Often called “artificial muscles,” these materials change size or shape when stimulated by an electric field.

- Dielectric Elastomer Actuators (DEAs): A soft insulating layer sandwiched between two compliant electrodes. When voltage is applied, the electrodes attract each other, squeezing the insulator and causing it to expand sideways.

- Pros/Cons: They are silent and fast. However, they typically require very high voltages (thousands of volts), which poses safety challenges for human interaction.

4. Thermal and Chemical Actuation

Some soft robots move via chemical reactions that produce gas (to inflate chambers) or heat (to trigger shape memory alloys). These are less common for general-purpose robots but useful for fully autonomous “wild” robots that forage for fuel.

Sensing and Control: The “Nervous System”

This is currently the hardest problem in bio-inspired soft robotics.

In a rigid robot, if you know the angle of the elbow and the angle of the wrist, you know exactly where the hand is. This is called “kinematics.”

In a soft robot, the arm has infinite degrees of freedom. It can twist, stretch, compress, and bend at any point. Traditional sensors (like rigid encoders) don’t work because they prevent the robot from stretching.

Soft Sensors

To give these robots “proprioception” (the sense of body position), engineers are developing stretchable sensors.

- Liquid Metal Channels: Channels filled with liquid metal (like Galinstan) change electrical resistance when stretched. By measuring the resistance, the robot knows how much it has stretched.

- Optical Fibers: Stretchable optical fibers detect changes in light transmission as the robot bends.

Learning to Move (AI and Control)

Because the physics of soft bodies is so complex, standard mathematical models often fail. Engineers are turning to Model-Free Reinforcement Learning.

- How it works: Instead of programming the robot with the laws of physics, the AI controls the robot in a simulation (or real life) and “learns” how to move by trial and error.

- Example: A soft robotic hand might try 1,000 different ways to pick up a pen before figuring out the optimal air pressure sequence to achieve a stable grip.

Real-World Applications

Bio-inspired soft robotics is moving out of the lab and into the real world. Here is where the technology is making an impact as of early 2026.

1. Healthcare and Rehabilitation

This is the most immediate and valuable sector for soft robotics.

- Soft Rehabilitation Gloves: Stroke survivors often lose hand function. A soft robotic glove with pneumatic actuators can gently force the hand open and closed, performing physical therapy exercises at home.

- Minimally Invasive Surgery: Soft robots can stiffen and soften on command. A soft catheter can navigate the tortuous veins of the brain to treat an aneurysm without puncturing delicate vessel walls, essentially “snaking” its way to the problem site.

- Patient Transfer: Soft, inflatable mats are used to lift elderly or immobile patients from beds to stretchers, distributing force evenly to prevent bruising or bedsores.

2. Agriculture and Food Processing

Agriculture faces a labor shortage, but rigid robots are terrible at picking produce.

- Delicate Harvesting: A metal claw crushes a strawberry. A bio-inspired soft gripper uses “form closure” to envelop the berry and twist it off the stem without applying high pressure.

- Food Handling: In factories, soft grippers handle chocolates, breads, and eggs at high speeds. These grippers are hygienic (easy to wash silicone) and don’t require complex vision systems to determine the exact shape of every distinct chicken nugget.

3. Search and Rescue

When buildings collapse, the voids are small, unstable, and jagged.

- Rubble Navigation: A rigid rover cannot climb over loose debris easily. A snake-like or worm-like soft robot can slither into crevices to search for survivors.

- Durability: If a rock falls on a soft robot, it deforms but usually survives. A rigid robot would likely suffer a bent axle or shattered casing.

4. Deep Sea Exploration

The deep ocean exerts crushing pressure. To protect rigid robots, we build heavy, expensive titanium pressure hulls.

- Soft Deep-Sea Robots: Because soft robots are mostly solid silicone or liquid-filled, they are essentially incompressible. They do not need pressure hulls. A soft robot built by Harvard researchers successfully operated at the bottom of the Mariana Trench (over 10,000 meters deep) without a heavy metal shell.

Common Challenges and Pitfalls

Despite the excitement, bio-inspired soft robotics is not a silver bullet. There are significant hurdles preventing widespread adoption.

1. The Puncture Problem

The greatest strength of soft robots is also their weakness: softness. Sharp objects, thorns, broken glass, or even a cat’s claw can puncture pneumatic chambers.

- Mitigation: Researchers are developing “self-healing” materials (polymers that reform bonds) and composite skins (like Kevlar mesh) that allow flexibility but resist cutting.

2. The Power Tether

Most pneumatic soft robots require a compressor to supply air. This usually means the robot is tethered to a bulky box on a table.

- The Challenge: Making soft robots autonomous is hard because pumps, batteries, and valves are traditionally heavy and rigid.

- Solution: Scientists are miniaturizing soft pumps and exploring chemical actuation (gas generation) to eliminate the need for heavy compressors.

3. Precision and Payload

Soft robots are generally “weak” compared to rigid robots. They cannot lift heavy car engines. Furthermore, they lack precision. A soft arm might vibrate or sag under gravity, making it unsuitable for tasks requiring sub-millimeter accuracy (like soldering).

4. Speed

Pneumatic robots are limited by the speed of sound in air and the flow rate through tubes. They generally move slower than electric motors. While explosive actuation (combustion) exists, it is dangerous and hard to control.

The Future: Evolution of the Soft Machine

As we look toward the latter half of the 2020s, bio-inspired soft robotics is merging with other disciplines to create “hybrid” technologies.

Variable Stiffness

The holy grail of soft robotics is a machine that can switch between soft and rigid on demand—just like an octopus can stiffen its arm to push objects. Technologies like granular jamming (vacuum-packing coffee grounds creates a solid brick; releasing the vacuum makes it fluid) are being integrated into soft skins. This allows a robot to squeeze through a hole (soft) and then bridge a gap (rigid).

Biodegradable Robotics

Since soft robots are made of polymers, there is a push to make them biodegradable. Imagine a swarm of environmental monitoring robots released into a forest. After gathering data on soil health, they simply decompose into compost, leaving no electronic waste behind.

Living Machines (Bio-Hybrids)

The frontier of this field is the integration of actual living tissue. “Xenobots” and similar bio-hybrid projects use living muscle cells grown on soft scaffolds to drive movement. These robots heal themselves perfectly because they are alive, and they run on glucose rather than batteries. While currently microscopic and experimental, they represent the ultimate convergence of biology and robotics.

Conclusion

Bio-inspired soft robotics is more than just a new way to build machines; it is a philosophy of humility. It acknowledges that after millions of years of trial and error, nature has solved mobility and manipulation problems in ways that rigid engineering initially overlooked.

By trading stiffness for compliance and precision for adaptability, we are creating machines that can finally work alongside us safely. From the gloves that help stroke patients regain their independence to the robotic worms exploring the ruins of disaster zones, these soft, squishy machines are reshaping our future—one flex at a time.

Next Steps for Enthusiasts

If you are interested in this field, you do not need a PhD to start.

- Look up “Soft Robotics Toolkit”: An open-source resource with files and guides to build your own soft parts.

- Experiment with Silicone: You can cast basic actuators at home using 3D printed molds and RTV silicone.

- Follow the Research: Keep an eye on labs like the Wyss Institute (Harvard) or MIT CSAIL, as they frequently publish breakthrough designs.

Frequently Asked Questions (FAQs)

1. Are soft robots stronger than rigid robots? Generally, no. Rigid robots (like factory arms) are designed for high payload and force. Soft robots are designed for adaptability and safety. However, some soft actuators, particularly those using fiber-reinforced hydraulics, can lift distinctively heavy loads relative to their own weight, but they usually lack the absolute strength of steel hydraulics.

2. How do you power a soft robot without a plug? This is a major challenge. Autonomous soft robots carry miniature pumps, compressed air cartridges (CO2 canisters), or batteries. Some experimental robots use chemical reactions (like decomposing hydrogen peroxide) to generate gas pressure internally, eliminating the need for heavy pumps.

3. Can soft robots break easily? They are resilient to blunt force (you can hit them with a hammer, and they won’t dent), but they are vulnerable to sharp objects. Punctures can disable pneumatic robots. Advances in self-healing materials are critical to solving this issue.

4. What industries use soft robotics today? The two largest adopters are the food industry (for handling delicate items like cakes and produce) and the medical device industry (for rehab gloves, soft exosuits, and minimally invasive surgical tools).

5. Is 3D printing used in soft robotics? Yes, extensively. 3D printing is used to create the molds for casting silicone actuators. Furthermore, advances in multi-material 3D printing now allow engineers to print soft and hard materials simultaneously, creating complex robots in a single print job without assembly.

6. What is the difference between soft robotics and biomimicry? Biomimicry is the broad practice of taking inspiration from nature. Soft robotics is a specific field of engineering. Soft robotics uses biomimicry as a design principle, but not all biomimicry is soft robotics (e.g., a rigid drone wing inspired by a bird is biomimicry but not soft robotics).

7. Are bio-inspired robots essentially cyborgs? Most are not. Bio-inspired usually means “synthetic materials designed to look/act like biology.” However, the sub-field of “bio-hybrid” robotics does combine synthetic skeletons with living tissue (like frog muscle cells), which is closer to the definition of a cyborg or a biological machine.

8. Why are octopuses such a common inspiration? Octopuses are “muscular hydrostats,” meaning they have no bones and can move in virtually any direction. This represents the ultimate goal of soft robotics: infinite degrees of freedom. Mimicking the octopus allows engineers to break away from the limitations of rigid joints and hinges.

References

- Rus, D., & Tolley, M. T. (2015). Design, fabrication and control of soft robots. Nature, 521(7553), 467-475. https://www.nature.com/articles/nature14543

- Polygerinos, P., et al. (2017). Soft Robotics: Review of Fluid-Driven Intrinsically Soft Devices; Manufacturing, Sensing, Control, and Applications in Human-Robot Interaction. Advanced Engineering Materials. https://onlinelibrary.wiley.com/doi/abs/10.1002/adem.201700016

- Wyss Institute at Harvard University. (n.d.). Soft Robotics. Retrieved from

- Soft Robotics Toolkit. (n.d.). Open Source Documentation for Soft Robotics Design. Retrieved from https://softroboticstoolkit.com/

- Cianchetti, M., et al. (2018). Bio-inspired soft robotics: Material selection, actuation, and design. Handbook of Materials for Nano- and Micro-technologies.

- NASA. (2023). Soft Robotics for Space Exploration. NASA Jet Propulsion Laboratory. Retrieved from https://www-robotics.jpl.nasa.gov/

- Shepherd, R. F., et al. (2011). Multigait soft robot. Proceedings of the National Academy of Sciences, 108(51), 20400-20403. (The foundational “Soft Robot” paper).

- IEEE Robotics and Automation Society. (2024). Soft Robotics (SoRo) Journal. Retrieved from https://www.ieee-ras.org/publications/t-ro