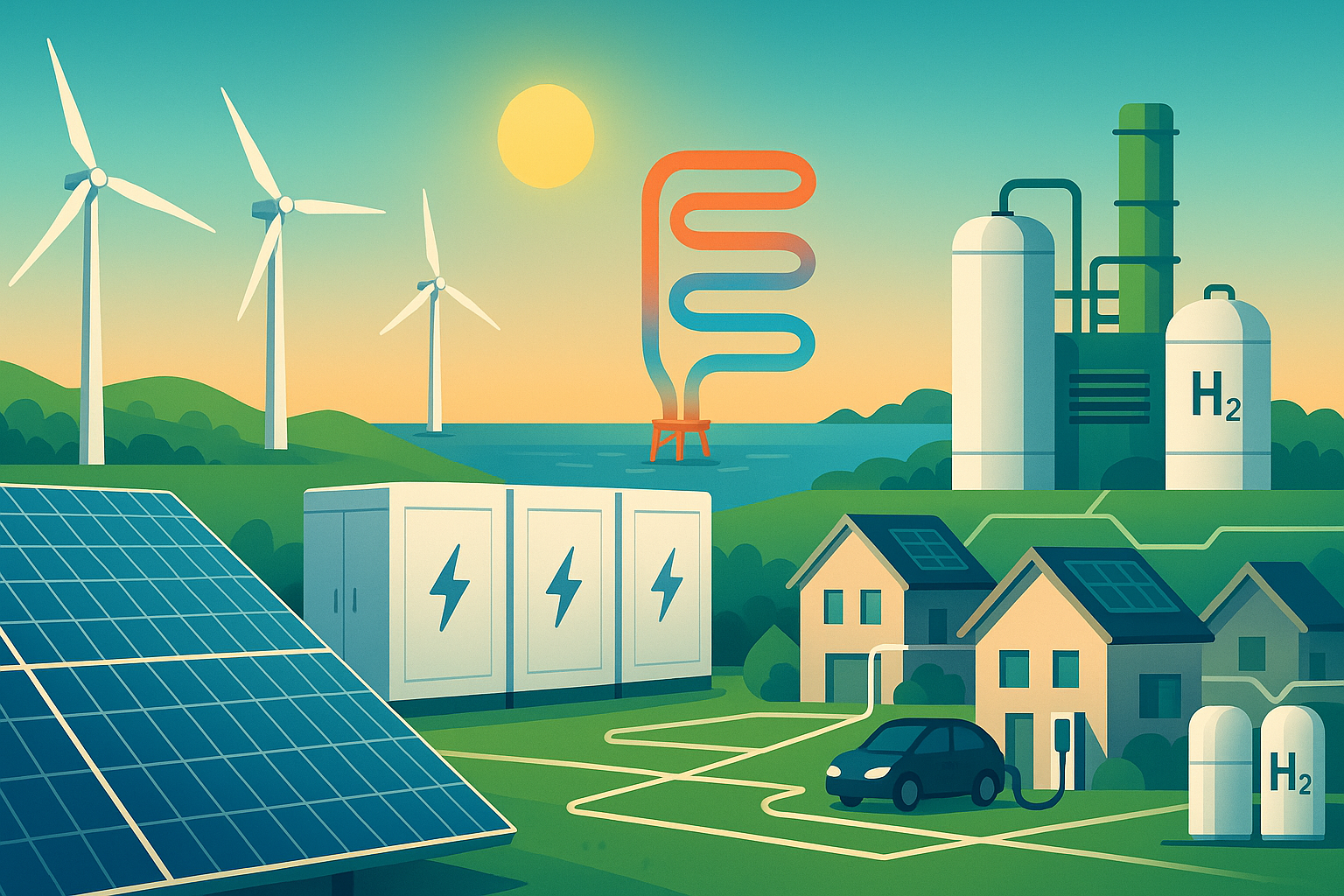

Green technology has moved from a niche to the engine room of the global economy. From offshore wind to ultra-low-carbon solar, from battery gigafactories to direct air capture, the leaders are those turning lab-tested ideas into bankable, scalable solutions—at industrial speed. This guide highlights 10 companies leading the charge in green technology, what each actually does, and—crucially—how you can implement their solutions in your organization with clear steps, prerequisites, metrics, safety notes, and mini-plans you can run this quarter.

Disclaimer: The information below is for general education and planning only. It is not investment, legal, engineering, or tax advice. Consult qualified professionals for advice tailored to your situation.

Key takeaways

- Execution beats hype: Each featured company pairs proven tech with robust delivery models (PPAs, turnkey EPC, subscription software, fleet leases).

- Start small, scale fast: Pilot in weeks (one building, one site, one route), then scale using standardized designs, repeatable procurement, and performance-based contracts.

- Measure to manage: Track a handful of KPIs—emissions avoided (tCO₂e), energy intensity (kWh/ft²), uptime, round-trip efficiency, capacity factor, and simple payback.

- Design for constraints: Interconnection timelines, permitting, grid capacity, and supply-chain lead times are real; build buffers and pre-qualify vendors.

- Portfolio thinking wins: Stack solutions—efficiency + electrification + renewables + storage + offsets (as a last mile)—to hit targets reliably and on budget.

Quick-start checklist (for sustainability and operations leaders)

- Clarify the “why”: Compliance, cost stability, brand, or science-based targets? Your “why” sets priority and risk tolerance.

- Baseline: Pull a 12-month utility data export, fleet fuel logs, and facility floor area. Create a one-page baseline of energy, emissions, and spend.

- Pick one of each: One building efficiency platform, one on-site or off-site renewable deal, one storage or demand-flex pilot, and one mobility pilot.

- Decide your contract model: Capex, PPA/lease, energy-as-a-service, or subscription.

- Set three KPIs: Emissions avoided, energy cost variance vs. budget, and uptime/service-level compliance.

- Governance: Name a single-threaded owner, agree on a weekly 30-minute stand-up, and a monthly steering review.

- Permits & safety: Identify permits, grid studies, and site safety protocols early; appoint a responsible engineer of record.

Ørsted — Building the backbone of offshore wind

What it is & why it matters

Ørsted develops and operates large-scale offshore wind, onshore wind/solar, and energy storage. The company’s offshore fleet delivers utility-scale, zero-fuel electricity with strong capacity factors and multi-decade lifetimes. Recent milestones include commissioning the first commercial-scale U.S. offshore wind farm and a multi-gigawatt U.S. buildout plan—expanding clean generation at coastal load centers where grid constraints are tight.

Core benefits: predictable output, zero fuel price risk, long-lived assets, and the ability to anchor corporate PPAs with meaningful additionality.

Requirements & prerequisites

- Buy-side: Creditworthy offtaker (corporate PPA/sleeved PPA), or municipal/utility procurement authority.

- Site & grid: Coastal interconnection capacity and regional REC frameworks.

- Skills & tools: PPA negotiation experience, volumetric risk management, renewable accounting, and contract management.

Lower-cost alternative: Community solar, onshore wind, or virtual PPAs where offshore is unavailable.

Step-by-step (beginner)

- Load & risk profile: Map hourly load, hedge needs, and emissions.

- Market screening: Identify eligible offshore wind projects and REC regimes.

- Commercial path: Choose physical vs. virtual PPA, term (10–20 years), and price structure (fixed, indexed).

- RFP & diligence: Run a competitive process, assess curtailment and basis risk, and review interconnection status.

- Contracts & accounting: Finalize PPA, REC transfer, and hedge accounting treatment; set reporting.

Beginner modifications & scaling

- Start small: Cover 10–20% of load with a virtual PPA, then layer additional tranches.

- Scale: Add onshore renewables near facilities for diversity; integrate storage PPAs to shape profile.

Recommended KPIs

- Emissions avoided (tCO₂e/yr), hedge effectiveness vs. budget, contract uptime, and settlement variance.

Safety & caveats

- Interconnection delays, marine logistics, and policy changes create timeline risk; model schedule contingency and include force-majeure language.

Mini-plan

- Week 1–2: Baseline load and risk; shortlist two projects.

- Week 3–4: Price discovery; choose structure; tee up internal approvals.

NextEra Energy — Utility-scale renewables, storage, and PPAs at scale

What it is & why it matters

NextEra develops and operates some of the world’s largest portfolios of wind, solar, and grid-scale batteries, with deep experience signing long-tenor PPAs and delivering interconnection-ready projects. For large buyers, they offer a clear path to lock in long-term clean power and capacity.

Requirements & prerequisites

- Counterparty readiness: Investment-grade or equivalent credit support.

- Data: Hourly load, renewable energy strategy, and REC treatment preferences.

- Internal: Legal/treasury alignment on contract terms and hedge accounting.

Low-cost alternative: Shorter-tenor VPPA tranches or certified EACs while larger projects queue.

Step-by-step

- Portfolio approach: Define desired split across wind, solar, and storage to match your load shape.

- Engage developers: Request project lists with COD windows and interconnection status.

- Compare offers: Evaluate LCOE, basis/curtailment risk, and balancing costs.

- Close & monitor: Execute PPA; track monthly settlement and REC retirement.

Beginner modifications & scaling

- Pilot with a 25–50 MW VPPA slice before expanding to 100–300 MW multi-site tranches.

KPIs

- Contracted MWh delivered vs. plan, settlement costs, emissions avoided, and price variance to budget.

Safety & caveats

- Transmission constraints and policy shifts can alter COD; include schedule protections and alternative supply clauses.

Mini-plan

- Week 1: Load/hedge brief; align on objectives.

- Week 2–4: Shortlist projects and terms; run sensitivity; down-select one offer.

Iberdrola — Global renewable utility & U.S. grid-connected growth

What it is & why it matters

Iberdrola (through affiliates in key markets) develops and operates wind, solar, storage, and regulated networks. Their combination of generation and grid assets is valuable for data center and industrial customers that need clean electrons connected to real load in growing U.S. nodes.

Requirements & prerequisites

- Buyer profile: Large C&I, hyperscale, or municipal/coop utility.

- Contracts: PPA or behind-the-meter interconnection agreements where available.

- Sites: Land availability for on-site where applicable; otherwise off-site PPAs.

Lower-cost alternative: REC-backed retail supply while grid projects complete.

Step-by-step

- Load mapping: Identify priority states and interconnection queues near your facilities.

- Project match: Shortlist in-construction or near-NTP assets to limit schedule risk.

- Negotiate: Secure price, term, and delivery point; align on green attributes.

- Integrate: Match delivery profile to facility operations and demand response.

Beginner modifications & scaling

- Start with one state; add sister projects in adjacent balancing authorities to diversify basis risk.

KPIs

- Delivered GWh vs. PPA schedule, curtailment rate, emissions avoided, and contract compliance.

Safety & caveats

- Local permitting and community engagement are critical; build engagement plans early.

Mini-plan

- Weeks 1–2: Identify top two geographies; request project sheets.

- Weeks 3–4: Run cost/benefit; secure internal approvals to negotiate LOI.

Vestas — Wind turbines and turnkey services for onshore & offshore

What it is & why it matters

Vestas designs and services wind turbines with a global install base across onshore and offshore projects. For developers and utilities, turbine selection, service contracts, and availability guarantees determine a wind farm’s lifetime economics.

Requirements & prerequisites

- Developers/owners: Site control, wind resource assessment, interconnection studies.

- Skills: EPC management, geotech, and O&M planning.

- Financing: Capex, tax equity/transferability where applicable, and long-term service agreements.

Lower-cost alternative: Community-scale projects or repowering existing sites with uprated rotors.

Step-by-step

- Resource & layout: Complete met mast/LiDAR and micro-siting.

- Tech selection: Match rotor, hub height, and IEC class to wind regime.

- Contracts: Secure supply, logistics, crane windows, and long-term service with availability guarantees.

- Commission & monitor: Use condition-based monitoring and SCADA analytics to maintain >97% availability.

Beginner modifications & scaling

- Pilot a repower of 10–20 MW at an existing site before building a new 100–200 MW project.

KPIs

- Net capacity factor, turbine availability, wake losses, and LCOE.

Safety & caveats

- Crane mobilization/weather risk, grid constraints, and wildlife permitting need early mitigation.

Mini-plan

- Weeks 1–2: Validate wind study and interconnection status; draft tech spec.

- Weeks 3–4: Request turbine bids with delivery windows; compare availability/O&M terms.

First Solar — Ultra-low-carbon thin-film modules, U.S. manufacturing & recycling

What it is & why it matters

First Solar manufactures cadmium telluride thin-film modules with efficient U.S.-based factories and closed-loop recycling. These modules provide strong energy yield in hot climates, fast ramping U.S. supply, and verifiable low embodied carbon—useful for buyers prioritizing domestic content and lifecycle impact.

Requirements & prerequisites

- Project type: C&I rooftops/ground-mount and utility-scale.

- Team: EPC partner familiar with thin-film strings and higher voltage designs.

- Commercials: Module supply agreement and safe-harbor/tax credit strategy.

Lower-cost alternative: Standard crystalline silicon with independent low-carbon certification when thin-film supply is constrained.

Step-by-step

- Site screening: Load, roof/land, interconnection, and structural checks.

- Design: Optimize for temperature coefficients and bifacial vs. monofacial tradeoffs (thin-film is monofacial).

- Procurement: Lock module supply and delivery schedule; align on recycling program enrollment.

- Install & commission: Follow manufacturer QA/QC; set inverter telemetry and performance ratios.

Beginner modifications & scaling

- Start with a 1–5 MW pilot at a warehouse campus; scale to multi-site portfolio using standard BoS kits.

KPIs

- Performance ratio, specific yield (kWh/kWp), embodied carbon per watt, and O&M response time.

Safety & caveats

- Plan end-of-life recycling from day one; verify module handling and waste compliance.

Mini-plan

- Week 1: EPC walk-through and concept design.

- Weeks 2–4: Lock module allocation and file interconnection; order BoS.

Schneider Electric — Digital energy & building decarbonization platform

What it is & why it matters

Schneider provides hardware-plus-software for building energy management, electrification, and grid-interactive operations. Its platform brings HVAC, lighting, metering, and controls into a single analytics layer to cut energy waste and enable demand flexibility—often with subscription models that shorten payback.

Requirements & prerequisites

- Sites: BMS-capable facilities or retrofit-ready buildings.

- Data: Metering points, asset inventory, and network access.

- People: Facility ops willing to adopt remote monitoring and playbooks.

Low-cost alternative: Start with sub-metering and fault detection on a subset of equipment.

Step-by-step

- Audit: Identify top energy systems and comfort issues.

- Connect: Install gateways, integrate existing controls, and map points.

- Automate: Apply schedules, setpoints, and fault detection & diagnostics (FDD).

- Optimize: Use analytics to target retro-commissioning and demand response.

Beginner modifications & scaling

- Start with one midsize site; roll out a “golden configuration” to similar buildings.

KPIs

- Energy intensity (kWh/m²), comfort score, avoided maintenance calls, and demand-response earnings.

Safety & caveats

- Cybersecurity and change management: segment networks and train staff; deploy rollback plans for control strategies.

Mini-plan

- Week 1: Install gateways; connect 100–200 points.

- Weeks 2–4: Enable FDD; implement schedules; verify savings weekly.

Tesla — Grid-scale and behind-the-meter energy storage

What it is & why it matters

From residential systems to multi-gigawatt-hour utility deployments, Tesla’s energy storage platforms provide fast-responding capacity for arbitrage, peak-shaving, and resilience. Storage is now a foundational complement to intermittent renewables, with deployments scaling rapidly worldwide.

Requirements & prerequisites

- C&I sites: Demand charges, load flexibility, and adequate electrical room or yard space.

- Utility projects: Interconnection queue position and dispatch market participation.

- Ops: EMS integration, tariff study, and safety plan.

Lower-cost alternative: Community battery programs or smaller modular systems while larger interconnection is pending.

Step-by-step

- Tariff & use-case modeling: Peak reduction, TOU arbitrage, demand response, or backup.

- Sizing & siting: Validate electrical infrastructure, ventilation, and fire code compliance.

- Procurement: Turnkey EPC or equipment-only with certified installers.

- Commission & operate: Set EMS, warranties, and operating profiles; train staff.

Beginner modifications & scaling

- Start with a 250–500 kW/1–2 MWh pilot at the highest-demand site; then replicate.

KPIs

- Round-trip efficiency, cycle count, peak reduction (kW), avoided demand charges, and uptime.

Safety & caveats

- Follow fire codes and spacing; coordinate with AHJ and insurers; set SOC and temperature limits per OEM guidance.

Mini-plan

- Week 1: Tariff deep-dive, load study.

- Weeks 2–4: Site walk; size system; submit interconnection and permit.

BYD — Electrified fleets from sedans to buses and trucks

What it is & why it matters

BYD manufactures electric cars, buses, and trucks at massive scale. For organizations electrifying fleets or transit, its portfolio enables quick emissions cuts with total-cost-of-ownership gains, especially on high-utilization routes.

Requirements & prerequisites

- Use case: Fixed routes, depot charging, or workplace charging.

- Infrastructure: Chargers, load capacity, and demand charge strategy.

- People & process: Driver training, telematics, and maintenance planning.

Lower-cost alternative: Begin with plug-in hybrids on demanding routes while charging is built.

Step-by-step

- Fleet diagnostics: Identify routes with predictable dwell times.

- Charger plan: Decide on AC vs. DC, power levels, and utility incentives.

- Pilot procurement: Lease or buy 5–20 vehicles plus chargers at one depot.

- Operate & optimize: Use telematics for charging windows and driver coaching.

Beginner modifications & scaling

- Start with pool cars or one bus route; scale to full depot conversions with managed charging and on-site solar/storage.

KPIs

- Fuel/energy cost per km, uptime, maintenance cost per vehicle, avoided CO₂ per route.

Safety & caveats

- Plan for cold/heat range variance; mitigate demand charges with scheduled charging or on-site storage.

Mini-plan

- Week 1: Pick a pilot route and depot.

- Weeks 2–4: Order chargers; schedule utility service upgrade; place vehicle order.

CATL — The battery maker behind EVs and grid storage

What it is & why it matters

CATL supplies EV and energy-storage batteries globally, enabling long-range vehicles and increasingly bankable stationary storage. For fleet operators and storage developers, access to high-volume, reliable cells and integrated battery systems is critical to scale.

Requirements & prerequisites

- For fleets: Vehicle models using supported chemistries; charging plan.

- For storage developers: Integrator/OEM using CATL modules; EMS compatibility.

- Commercials: Warranty, service network, and spare module strategy.

Lower-cost alternative: Second-life batteries for low-cycle, low-criticality applications.

Step-by-step

- Chemistry match: Choose LFP or NMC by duty cycle, energy density, and cost.

- Partner integrator: Select a certified integrator for ESS with grid code compliance.

- Testing & acceptance: Specify factory acceptance tests, fire safety, and UL certifications.

- Operate: Define cycling limits and warranty-compliant dispatch.

Beginner modifications & scaling

- Pilot a 1–5 MWh ESS at a site with high demand charges; scale to 20–100+ MWh multi-site.

KPIs

- Degradation per cycle, effective round-trip efficiency, thermal stability events, and maintenance turnaround.

Safety & caveats

- Ensure cell traceability and incident response plans; follow OEM thermal and BMS guidance.

Mini-plan

- Week 1: Define duty cycle and power/energy ratio.

- Weeks 2–4: Select integrator; finalize safety design; schedule delivery.

Climeworks — Permanent carbon removal via direct air capture

What it is & why it matters

Climeworks removes CO₂ directly from ambient air and stores it underground, offering durable carbon removal for emissions you cannot abate immediately (e.g., process emissions or interim portfolio gaps). It complements, not replaces, decarbonization.

Requirements & prerequisites

- Corporate buyer: Clear internal carbon price or budget for durable removals.

- Accounting: Removal certificates integrated into your GHG inventory.

- Strategy: Use removals only after prioritized abatement and efficiency.

Lower-cost alternative: Nature-based credits with robust permanence and leakage safeguards—always after abatement.

Step-by-step

- Set a removal tranche: E.g., 5–10% of annual residual emissions.

- Contract: Enter multi-year offtake with staged volumes as capacity scales.

- Report: Integrate verified retirements into sustainability reports.

Beginner modifications & scaling

- Start with a small subscription; ramp volumes as new plants come online and abatement progresses.

KPIs

- tCO₂ removed and verified, share of residual emissions covered, and cost per tCO₂.

Safety & caveats

- Be transparent; avoid using removals to delay direct abatement.

Mini-plan

- Week 1: Quantify residual emissions.

- Weeks 2–4: Execute a small offtake; publish accounting approach.

How to measure progress (simple, dependable KPIs)

- Emissions: tCO₂e avoided/removed vs. baseline; % of load matched with renewables hourly and annually.

- Energy cost: Variance vs. budget; hedge effectiveness (PPA/VPPAs).

- Reliability: Uptime of assets (turbines, inverters, BESS), and building comfort score.

- Project delivery: Schedule variance, interconnection status, and change-order count.

- Finance: Realized payback / IRR vs. plan; incentive capture rate.

Troubleshooting & common pitfalls

- Interconnection surprise: Queue delays derail COD. Mitigation: prioritize in-construction projects, require milestone reporting, and include alternate delivery clauses.

- Controls drift in buildings: Savings fade after six months. Mitigation: monthly commissioning sprints and automated alerts.

- Demand charges spike: New EV fleets trigger unexpected bills. Mitigation: managed charging, TOU alignment, and buffer storage.

- Under-spec’d O&M: Wind/solar underperform without proactive maintenance. Mitigation: lock service SLAs and condition-based monitoring.

- Over-reliance on offsets: Reductions stall. Mitigation: abate first; cap removals as a defined share of residuals.

A simple 4-week starter plan (from zero to momentum)

Week 1 — Baseline & shortlist

- Pull 12 months of utility and fuel data; compute emissions and spend.

- Pick one company each for: (1) building optimization, (2) renewables PPA, (3) storage or fleet pilot, (4) removals.

- Draft success metrics and a risk register.

Week 2 — Site & tariff studies

- Conduct a walk-through at one building and one fleet depot.

- Run a storage tariff model and a solar/battery site screen.

- Request project sheets/PPAs from two renewable developers.

Week 3 — Commercial shape & design

- Select contract models (subscription, lease/PPA, or capex).

- Fix preliminary size (kW/MWh, MW) and target COD.

- Draft internal investment memo with KPI dashboard.

Week 4 — Commit to pilots

- Sign one building controls subscription, one fleet/charging pilot, and one small VPPA or REC bridge.

- Approve a small removals offtake linked to your residual emissions.

- Schedule monthly steering and quarterly board updates.

FAQs

1) Which should I do first—efficiency, renewables, storage, or EVs?

Start with efficiency and controls. It lowers the size (and cost) of everything else and delivers immediate savings. Then add off-site renewables or a small VPPA, and a targeted storage/fleet pilot.

2) Are virtual PPAs risky in volatile power markets?

They carry basis and settlement risk. Use diversified portfolios, floor/collar pricing where available, and choose projects with strong interconnection status to minimize curtailment.

3) How do I justify storage if my utility rates are flat?

Target demand charge reduction, backup power, and demand response. In some markets, resilience and avoided outage costs justify storage even without time-of-use spreads.

4) Are thin-film solar panels safe and recyclable?

Yes—designed and tested to rigorous standards, with manufacturer-run recycling programs that recover high percentages of materials. Include recycling enrollment in your procurement.

5) Will electric buses or trucks work on long routes or in cold climates?

Plan for range buffers and managed charging. Start with depot-based routes and use preconditioning and thermal management; add on-site storage if depot demand charges rise.

6) Does direct air capture replace cutting my own emissions?

No. Use durable removals only for residual emissions after abatement. Publish a prioritization hierarchy so stakeholders see abatement comes first.

7) How do I avoid vendor lock-in with building controls?

Choose open protocols, vendor-agnostic platforms, and insist on data ownership clauses. Pilot on one site and port the configuration to test portability.

8) What’s a realistic timeline for a corporate VPPA?

If you select a near-NTP project, plan 3–6 months for diligence and contracting and 6–18 months to COD, depending on interconnection.

9) Are today’s batteries safe?

Modern systems meet strict standards and include BMS, thermal management, spacing, and fire-suppression. Engage local authorities early and follow manufacturer siting guidance.

10) How do I compare wind turbine offers?

Normalize net capacity factor, availability guarantees, O&M price escalators, and logistics/crane windows. Look at lifecycle LCOE, not just capex.

11) Will renewables still be cost-competitive this year?

Recent analyses show renewables remain among the most cost-competitive new generation sources on an unsubsidized basis in many markets. Always validate with your local tariffs and interconnection costs.

12) How do I keep projects on schedule?

Use a single-threaded owner, milestone-based contracts, and a weekly risk review focused on permits, interconnection, long-lead procurement, and AHJ sign-offs.

Conclusion

The companies above are not just symbols of a greener future—they are providers of ready-to-deploy systems that cut emissions and stabilize costs today. Choose one building to digitize, one route to electrify, one storage system to install, and one renewable PPA to sign. Then repeat.

CTA: Pick one pilot from this list today, book a 30-minute internal kickoff, and put your first clean megawatt—or avoided ton of CO₂—on the board this month.

References

- “Offshore Wind Energy & Our Wind Projects in the U.S.,” Ørsted U.S., n.d., https://us.orsted.com/renewable-energy-solutions/offshore-wind

- “Our Green Energy Transformation,” Ørsted U.S., n.d., https://us.orsted.com/about-us/our-green-energy-transformation

- “2025 American Action Report,” Ørsted, May 2025, https://cdn.orsted.com/-/media/www/docs/corp/us/whitepaper/rstedactionreportfinalspreadsdigital52.pdf

- “South Fork Wind — The First Commercial-Scale Offshore Wind Farm in the Nation,” NYSERDA executive summary, March 2024, https://www.nyserda.ny.gov/-/media/Project/Nyserda/Files/Programs/Offshore-Wind/ORST_Public-Executive-Summary.pdf

- “NextEra Energy fourth-quarter and full-year 2024 financial results,” NextEra Energy news release, Jan. 24, 2025, https://www.investor.nexteraenergy.com/news-and-events/news-releases/2025/01-24-2025-123043508

- “Investments of €17.3bn in the last year raise Iberdrola’s H1 2025 profit to €3.56bn,” Iberdrola newsroom, July 23, 2025, https://www.iberdrola.com/press-room/news/detail/iberdrola-boosts-h1-2025-profit-to-356bn-after-173bn-investment

- “Avangrid Energy Investments Generated Enough Electricity for 2.4 Million Homes in the First Half of 2025,” Avangrid newsroom, Aug. 2025, https://www.avangrid.com/w/avangrid-energy-investments-generated-enough-electricity-for-2.4-million-homes-in-the-first-half-of-2025

- “Wind Turbine Suppliers deliver new record volume despite difficult year full of diverse challenges,” Global Wind Energy Council, May 16, 2025, https://www.gwec.net/gwec-news/wind-turbine-suppliers-deliver-new-record-volume-despite-difficult-year-full-of-diverse-challenges

- “First Solar | Annual Report 2024,” First Solar, Mar. 31, 2025, https://s202.q4cdn.com/499595574/files/doc_financials/2024/ar/First-Solar-2024-Annual-Report-Web-Ready.pdf

- “First Solar issues 2024 Sustainability Report,” Semiconductor Today, Sept. 9, 2024, https://www.semiconductor-today.com/news_items/2024/sep/firstsolar-090924.shtml

- “Environmental Life Cycle Assessment of Electricity from PV systems — 2023 data update (slides),” IEA PVPS, May 2024, https://iea-pvps.org/wp-content/uploads/2024/05/Slides_IEA-PVPS-T12_Fact-Sheet-update-2023_v2.0.pdf

- “EcoStruxure Building Software,” Schneider Electric (product page), accessed Aug. 2025, https://www.se.com/us/en/work/software/ecostruxure-building/

- “EcoStruxure Building Activate — product page,” Schneider Electric USA, accessed Aug. 2025, https://www.se.com/us/en/product-range/254997161-ecostruxure-building-activate/

1 Comment