The manufacturing landscape is undergoing a fundamental shift, moving away from heavy, caged automation toward flexible, shared workspaces. At the heart of this transformation are collaborative robots, commonly known as cobots. Unlike their traditional industrial counterparts, which operate behind safety fences to prevent injury to humans, cobots are designed to work safely alongside people, augmenting human skills rather than replacing them entirely.

As of January 2026, the adoption of collaborative robots in manufacturing has accelerated beyond early adopter phases into mainstream production strategies. From small machine shops to massive automotive assembly lines, manufacturers are leveraging cobots to solve labor shortages, improve quality consistency, and introduce automation into high-mix, low-volume production environments where traditional automation was previously too costly or rigid.

In this guide, “collaborative robots” refers specifically to robotic arms and systems equipped with safety features—such as force feedback and collision detection—that allow uncaged operation in proximity to humans (following proper risk assessment). We will not cover autonomous mobile robots (AMRs) or warehouse logistics bots in depth, except where they integrate directly with manufacturing arms.

Key Takeaways

- Safety First: Cobots utilize advanced sensors and force-limiting technology to stop immediately upon contact, enabling safe interaction with human workers without heavy guarding.

- Flexibility: They are typically easier to program and redeploy than traditional robots, making them ideal for high-mix, low-volume production runs.

- Labor Augmentation: Cobots take over dull, dirty, and dangerous tasks (the “3 Ds”), allowing human workers to focus on cognitive tasks and complex problem-solving.

- Accessibility: Lower upfront costs and smaller footprints make automation accessible to Small and Medium-sized Enterprises (SMEs) that previously could not afford industrial robotics.

- Rapid ROI: Due to faster setup times and lower infrastructure costs (no cages), the Return on Investment (ROI) for cobots is often measured in months rather than years.

What Are Collaborative Robots (Cobots)?

A collaborative robot is a robot intended to physically interact with humans in a shared workspace. While traditional industrial robots are designed for speed, precision, and heavy payloads—often requiring strict physical separation from people—cobots prioritize safety and adaptability.

The defining characteristic of a cobot is its safety system. Most modern cobots adhere to Power and Force Limiting (PFL) standards. This means the robot monitors the torque at its joints and the force it exerts. If it encounters an obstruction—like a human arm—it stops instantly. This eliminates the need for the safety cages that dominate traditional automotive plants, freeing up valuable floor space.

Core Technical Features

- Rounded Geometry: Cobots often have rounded edges and soft casings to minimize impact force.

- Lightweight Construction: They are generally lighter than industrial robots, making them portable and easy to mount on mobile carts or various stations.

- Intuitive Programming: Many cobots utilize “hand-guiding” or “lead-through” programming, where a user physically moves the robot arm to waypoints to teach it a task, rather than writing complex code.

- Integrated Vision: Modern systems increasingly come with built-in vision systems or seamless integration with cameras to recognize parts without fixed jigging.

The Rise of Cobots in Modern Manufacturing

The industrial revolution introduced mechanization, and the third industrial revolution brought computerization and robotics. We are now firmly in the era of Industry 4.0 (and transitioning toward Industry 5.0), where the focus shifts back to the human element. Industry 5.0 emphasizes the collaboration between humans and machines, leveraging the unique creativity of people alongside the precision of robots.

Several factors are driving the explosion of collaborative robots in manufacturing:

- Labor Shortages: Manufacturing sectors globally are facing a skills gap. Older workers are retiring, and fewer younger workers are entering the trades. Cobots fill this gap by handling repetitive entry-level tasks.

- High-Mix, Low-Volume Demands: Consumers demand personalized products. Manufacturers need to switch production lines quickly. Traditional hard automation takes weeks to reconfigure; a cobot can be reprogrammed and moved to a new task in hours.

- Cost Reduction: The price of cobot hardware has stabilized, and the “total cost of deployment” is significantly lower than traditional robots because safety fencing and complex integration services are often unnecessary.

Collaborative Robots vs. Traditional Industrial Robots

Understanding the distinction between these two categories is vital for choosing the right tool for the job. Neither is strictly “better”; they serve different purposes.

| Feature | Collaborative Robots (Cobots) | Traditional Industrial Robots |

| Safety | Designed for safe interaction; stops on contact. | Requires safety cages/light curtains; dangerous to be near during operation. |

| Speed | Generally slower (restricted for safety). | Very high speeds. |

| Payload | Low to Medium (typically 3kg to 30kg). | High (can lift hundreds of kg). |

| Programming | User-friendly, low-code/no-code, hand-guiding. | Requires specialized programming skills (e.g., RAPID, KAREL). |

| Footprint | Small, compact, often mobile. | Large, fixed, requires dedicated floor space. |

| Primary Use | Shared tasks, flexible lines, SMEs. | High-speed mass production, heavy lifting. |

Decision Criterion: If your application requires moving heavy engine blocks at lightning speed with zero human presence, a traditional robot is the correct choice. If you need a robot to hand parts to a human operator or fit into a tight space on an existing manual line, a cobot is the superior option.

Key Benefits of Deploying Cobots

Implementing collaborative robots in manufacturing offers distinct advantages that go beyond simple automation.

1. Enhanced Worker Safety and Ergonomics

The most immediate benefit is the reduction of workplace injuries. Manufacturing is rife with Repetitive Strain Injuries (RSIs) caused by performing the same motion thousands of times a day. Cobots can take over these repetitive motions—such as loading a machine or screwing in a bolt—sparing human workers from chronic pain. Furthermore, by handling hazardous materials or operating in environments with extreme temperatures, cobots protect humans from acute risks.

2. Democratization of Automation

For decades, automation was the privilege of large conglomerates with multi-million dollar budgets. SMEs were locked out due to cost and complexity. Cobots have lowered the barrier to entry. A small job shop with 20 employees can now afford a cobot to tend a CNC machine, allowing the human operator to manage three machines instead of one, effectively tripling productivity without tripling headcount.

3. Improved Quality and Consistency

Humans get tired, distracted, or bored. A robot does not. In tasks requiring precise repeatability, such as applying a consistent bead of glue or tightening a screw to a specific torque, cobots ensure that every unit produced is identical. This reduces scrap rates and warranty claims.

4. Scalability and Flexibility

In a volatile market, agility is currency. A cobot mounted on a mobile cart can be tending a press brake in the morning and palletizing boxes in the shipping department in the afternoon. This flexibility allows manufacturers to adapt to seasonal demand spikes or changing product lines without investing in new, fixed machinery.

Top Applications for Cobots in Manufacturing

Cobots are versatile tools. While they can theoretically perform almost any motion a human arm can, certain applications have emerged as “sweet spots” where value is maximized.

Machine Tending

Machine tending—loading and unloading parts into a machine like a CNC mill, lathe, or press brake—is the single most common application for cobots in SMEs.

- The Problem: Operators often stand idle while the machine cuts the metal, only interacting to swap parts. It is boring and inefficient.

- The Cobot Solution: A cobot uses a gripper to pick a raw part, load it into the machine, wait for the cycle (or work on another machine), and then remove the finished part.

- Impact: This allows “lights-out” manufacturing, where machines continue running after the shift ends, utilizing the cobot to feed parts until the hopper is empty.

Palletizing and Packaging

End-of-line packaging involves lifting boxes and stacking them onto pallets. While the individual boxes might not be heavy, the cumulative weight lifted by a worker over a shift is massive.

- The Cobot Solution: Cobots equipped with vacuum grippers or large pads can stack boxes according to complex patterns.

- Why Cobots? They have a small footprint compared to massive industrial palletizers, fitting easily into existing packing areas.

Assembly and Screw Driving

Assembly tasks often require a “third hand” or precise repetition.

- The Cobot Solution: Cobots can hold a part in place while a human works on it, or they can perform the screwing and clipping tasks themselves.

- Force Sensing: Advanced cobots use force sensing to “feel” if a screw is cross-threaded or if a part isn’t snapping into place, creating a feedback loop similar to a human touch.

Quality Inspection

Visual inspection is visually taxing for humans.

- The Cobot Solution: A cobot with a high-resolution camera mounted on its wrist can inspect complex parts from multiple angles, checking for surface defects, missing components, or dimensional tolerances.

- Data: Unlike a human, the cobot can log the data of every inspection, providing a digital audit trail for quality control.

Welding

Welding requires high skill and a steady hand. There is a global shortage of skilled welders.

- The Cobot Solution: A cobot holds the welding torch. The skilled welder programs the path (often by moving the arm manually), and the robot executes the weld.

- Benefit: The human welder provides the expertise on settings and path, while the robot provides the steady hand and endurance. This extends the career of older welders and allows new welders to produce professional results faster.

Safety Standards and Risk Assessment

A common misconception is that cobots are “safe out of the box.” This is dangerous and incorrect. A cobot is a tool; if it is wielding a sharp knife or a hot welding torch, the system is hazardous regardless of the robot’s collision sensors.

As of 2026, the governing safety standards include:

- ISO 10218-1 and 10218-2: These provide requirements for industrial robots and robot systems.

- ISO/TS 15066: This is the technical specification specifically for collaborative robots. It defines the pain thresholds for various body parts and sets speed and force limits to ensure that if a collision occurs, it does not cause injury.

The Mandatory Risk Assessment

Before any cobot is deployed, a comprehensive risk assessment is mandatory. You must evaluate:

- The Robot: Its speed, reach, and force.

- The End-Effector: Is the gripper sharp? Pointed? Hot?

- The Workpiece: Is the part being moved heavy or sharp?

- The Environment: Are there pinch points between the robot and a wall or desk?

In practice: If a cobot is moving a scalpel, it is not safe to be near humans without guarding, even if it stops on contact. The contact itself would cause a cut. In such cases, safety scanners (lidar) are used to slow the robot down when a human approaches and stop it before they get within reach of the blade.

Challenges and Limitations

While cobots are transformative, they are not a magic bullet for every manufacturing problem.

- Speed Limitations: To be safe uncaged, cobots must move relatively slowly (often capped around 1 meter per second or less depending on the proximity of humans). If you need 100 picks per minute, a cobot is likely too slow.

- Payload Constraints: While heavy-duty cobots exist (lifting up to 30kg+), they are vastly outperformed by industrial robots that can lift 1000kg.

- Complexity of Safety: Achieving a truly safe “collaborative” application where the robot and human touch the same part simultaneously is difficult and requires rigorous validation. Most applications are actually “co-existence” (same space, different times) rather than true “collaboration.”

- Accuracy: While precise, cobots are generally slightly less rigid and accurate than high-end industrial robots due to the force sensors in their joints.

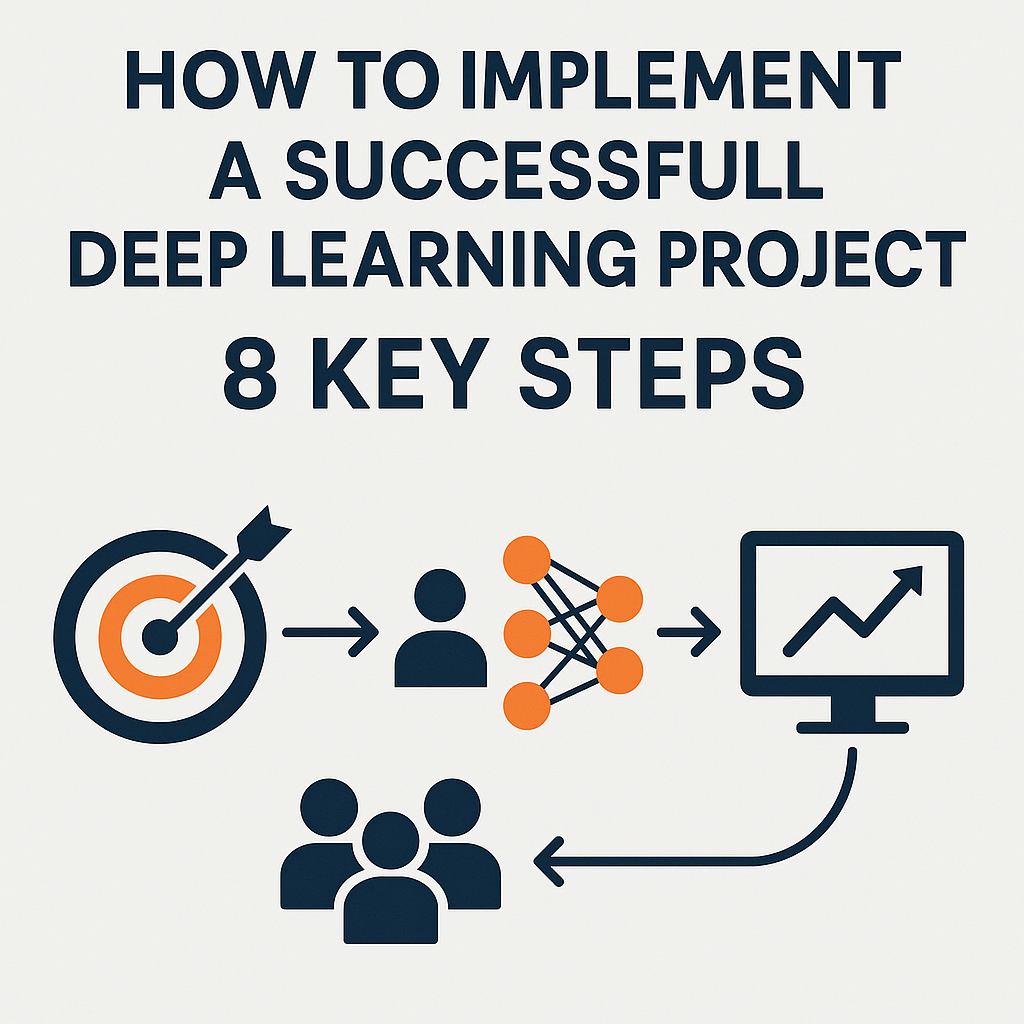

How to Implement Cobots: A Step-by-Step Framework

Deploying collaborative robots in manufacturing requires a strategic approach to ensure success. Do not buy the robot first and look for a problem later.

Phase 1: Assessment and Selection

- Identify the Pain Point: Look for bottlenecks. Where is WIP (Work in Progress) piling up? Where are workers complaining of fatigue? Where are the quality issues?

- Evaluate Suitability: Is the task repetitive? Is the payload under 20-30kg? Is the cycle time requirement moderate? If yes, it’s a candidate for a cobot.

- Calculate ROI: Factor in labor savings, scrap reduction, increased machine utilization, and recruitment cost savings.

Phase 2: Design and Integration

- Select the Robot: Choose a brand and model based on reach (how far it needs to stretch) and payload.

- Select the Peripherals: You need an “end-effector” (gripper), a base (stand or cart), and potentially a vision system.

- Safety Review: Perform the risk assessment before you finalize the design. Eliminate pinch points.

Phase 3: Deployment and Training

- Programming: Utilize the hand-guiding features to program the initial paths. Involve the operators in this process.

- Staff Buy-in: This is critical. Explain to workers that the robot is a tool to help them, not replace them. Give the robot a name. Workers who feel ownership over “their” robot are more likely to utilize it effectively.

- Testing: Run the robot at slow speeds initially. Verify safety stops.

Phase 4: Optimization

- Monitor Performance: Is the robot waiting on the machine? Is the machine waiting on the robot? Adjust speeds and logic to balance the line.

- Scale: Once the first cell is successful, replicate it across other machines.

Who This Is For (and Who It Isn’t)

This technology is for:

- High-Mix / Low-Volume Manufacturers: Job shops and contract manufacturers who need to change setups frequently.

- SMEs: Companies with limited floor space and budgets who cannot afford safety fencing.

- Assembly Plants: Facilities requiring humans and robots to work in close proximity.

- Companies with Labor Shortages: Firms struggling to hire for repetitive entry-level roles.

This technology is NOT for:

- High-Speed Mass Production: If you are bottling 500 beers a minute, you need traditional, caged, high-speed automation.

- Heavy Industry: Smelting, forging heavy ingots, or moving car chassis usually requires payloads beyond current cobot capabilities.

- Extremely Hazardous Environments: While some IP-rated cobots exist, extreme heat or corrosive environments are often better suited for specialized ruggedized industrial robots.

Future Trends in Collaborative Automation

As we look toward the latter half of the 2020s, collaborative robotics is merging with AI.

- AI-Driven Dexterity: Generative AI and reinforcement learning are enabling cobots to handle unstructured tasks, like picking jumbled parts out of a bin (bin picking) without rigid programming.

- Voice and Gesture Control: Future cobots will respond to voice commands or hand gestures, making interaction as natural as working with a human apprentice.

- Mobility: The combination of cobots with Autonomous Mobile Robots (AMRs) creates “mobile manipulators”—robots that can drive to a workstation, perform a task, and then drive to the warehouse to recharge or fetch parts.

- Ecosystem Integration: Plug-and-play ecosystems are expanding. Grippers, cameras, and software from different vendors are becoming increasingly interoperable, reducing integration time.

Related Topics to Explore

- Industrial Internet of Things (IIoT): Connecting cobots to the cloud for predictive maintenance.

- Lights-Out Manufacturing: Strategies for running production lines without human supervision overnight.

- Robot Operating System (ROS): The open-source middleware powering advanced robotic research and development.

- Digital Twins: Simulating cobot cells in a virtual environment before physical deployment to optimize layout.

- Lean Manufacturing: How automation fits into Kaizen and waste reduction philosophies.

Conclusion

Collaborative robots represent a democratization of manufacturing technology. By removing the cages and simplifying the interface, cobots have brought the power of automation to the factory floor worker. They are not merely replacement machines; they are productivity multipliers that allow manufacturers to remain competitive in a landscape defined by labor shortages and high customization demands.

For business leaders and plant managers, the question is no longer “should we automate?” but “how can we use collaborative automation to empower our workforce?” The journey starts with a simple assessment of the dull, dirty, and dangerous tasks on your floor today.

Ready to start? Begin by auditing your assembly line for high-repetition, low-weight tasks that currently cause bottlenecks.

FAQs

1. What is the difference between a cobot and an industrial robot? The main difference is safety and separation. Industrial robots are designed for high speed and heavy payloads and must be fenced off to prevent injury to humans. Cobots are equipped with sensors to detect collisions and limit forces, allowing them to operate safely alongside humans without cages (subject to risk assessment).

2. Are collaborative robots expensive? Generally, the hardware cost of a cobot is comparable to or slightly lower than a small industrial robot. However, the total cost of deployment is often significantly lower because you save on safety fencing, floor space, and expensive specialized programming services.

3. Do I need a specialized engineer to program a cobot? In most cases, no. Modern cobots utilize “teach pendants” (tablet-like controllers) and hand-guiding, allowing factory operators with no coding experience to program simple tasks. However, complex integrations with external sensors or logic may still require some technical expertise.

4. How safe are cobots really? Cobots are designed to be safe, but the application defines the safety. If a cobot is holding a sharp knife, it is dangerous. A risk assessment is legally required to ensure the entire system—robot, gripper, and part—is safe for human interaction.

5. What happens if a cobot bumps into a person? Cobots use Power and Force Limiting (PFL) technology. If they detect resistance—like bumping into a person—they are programmed to stop immediately. This reduces the impact force to a level unlikely to cause serious injury.

6. Can cobots work as fast as humans? It depends on the task. Humans are generally faster at complex, dexterous manipulation. Cobots are consistent. While a human might be faster for the first hour, a cobot maintains the same pace for 24 hours. For safety reasons, cobots usually move slower than traditional industrial robots.

7. What is the typical ROI for a cobot? The Return on Investment for cobots is typically fast, often between 6 to 18 months. This is due to the lower integration costs and the ability to run the robot for multiple shifts without overtime pay.

8. Can cobots handle heavy payloads? Most standard cobots handle between 3kg and 16kg. However, newer “heavy-duty” cobots are entering the market with payloads up to 30kg or more (as of 2026), specifically designed for palletizing heavier boxes.

9. Are cobots suitable for dirty or dusty environments? Many cobots come with IP54 or IP65 ratings, offering protection against dust and water splashes. For extremely harsh environments (like metal grinding or foundry work), protective covers or specialized ruggedized models may be necessary.

10. How do cobots integrate with existing machines? Cobots use standard communication protocols (like Modbus, Ethernet/IP, or discrete I/O) to “talk” to CNC machines, conveyors, and PLCs. This allows them to signal a machine to open a door, wait for the door to open, and then enter.

References

- International Organization for Standardization (ISO). (2016). ISO/TS 15066:2016 Robots and robotic devices — Collaborative robots. Geneva, Switzerland: ISO. https://www.iso.org/standard/62996.html

- International Federation of Robotics (IFR). (2025). World Robotics 2025: Industrial Robots. Frankfurt, Germany: IFR Statistical Department. https://ifr.org/worldrobotics

- Occupational Safety and Health Administration (OSHA). (n.d.). Robotics. United States Department of Labor. https://www.osha.gov/robotics

- Universal Robots. (n.d.). The Cobot Story. Retrieved from Official Documentation. https://www.universal-robots.com

- Fanuc America Corporation. (n.d.). Collaborative Robot Series. Official Product Documentation. https://www.fanucamerica.com

- National Institute of Standards and Technology (NIST). (2024). Performance Metrics for Collaborative Robots. U.S. Department of Commerce. https://www.nist.gov

- Robotics Industries Association (RIA). (2023). Collaborative Robot Safety: An Overview. Ann Arbor, MI: Association for Advancing Automation. https://www.automate.org