In the high-stakes world of modern manufacturing, silence is rarely golden. When the hum of machinery stops unexpectedly, money evaporates—often at a rate of thousands of dollars per minute. For decades, factory managers faced a difficult choice: repair machines only after they broke (reactive maintenance) or replace parts prematurely on a strict schedule (preventive maintenance), wasting useable life.

Today, AI predictive maintenance offers a third, superior path. By combining the sensing power of the Industrial Internet of Things (IIoT) with the analytical prowess of artificial intelligence, smart factories can now listen to their machines, understand their health in real-time, and predict failures days or weeks before they occur. This isn’t science fiction; it is the operational backbone of Industry 4.0.

This comprehensive guide explores how AI-driven predictive maintenance works, why it is becoming mandatory for competitive manufacturing, and how organizations can implement it effectively without drowning in data.

Key Takeaways

- Shift from Reactive to Proactive: AI predictive maintenance moves operations from “fix it when it breaks” to “fix it before it impacts production.”

- Data is the Fuel: Success depends less on the AI model itself and more on the quality and frequency of sensor data (vibration, temperature, acoustic).

- Cost Reduction: Properly implemented strategies can reduce maintenance costs by 25–30% and eliminate up to 70% of machine breakdowns.

- Integration is Key: Standalone AI models fail; successful systems must integrate with existing MES (Manufacturing Execution Systems) and ERP platforms.

- Human-in-the-Loop: AI provides the insight (“this bearing will fail in 48 hours”), but skilled technicians provide the context and execution.

Who This Is For (And Who It Isn’t)

This guide is written for plant managers, reliability engineers, IT/OT directors, and operations strategists who want to modernize their maintenance workflows. It covers both the strategic business case and the technical implementation framework.

It is not a coding tutorial for data scientists looking to write Python scripts for Random Forest algorithms, nor is it for home hobbyists looking to monitor a 3D printer. This is an enterprise-focused resource for industrial environments.

What Is AI Predictive Maintenance?

AI predictive maintenance (often abbreviated as PdM) is a strategy that uses data analysis tools and techniques to detect anomalies in operation and possible defects in equipment and processes so you can fix them before they result in failure.

Unlike traditional maintenance, which relies on the calendar or the clock (e.g., “change oil every 3 months”), predictive maintenance relies on the actual condition of the equipment. AI enters the picture by processing the massive streams of data generated by modern machinery—identifying subtle patterns, correlations, and trends that no human analyst could spot in a spreadsheet.

The Evolution of Maintenance Strategies

To understand the value of AI predictive maintenance, we must look at what it replaces. Most factories operate on a mix of the following legacy stages:

- Reactive Maintenance (Run-to-Failure): The machine runs until it breaks.

- Pros: Zero upfront cost.

- Cons: Catastrophic unplanned downtime, collateral damage to other machine parts, overtime labor costs, and missed delivery deadlines.

- Preventive Maintenance (Calendar-Based): Maintenance is performed on a schedule (e.g., every 500 cycle hours).

- Pros: Fewer catastrophic failures than reactive approaches.

- Cons: Highly inefficient. You might replace a perfectly good bearing just because the schedule says so. Statistics show that up to 30% of preventive maintenance activities are unnecessary.

- Condition-Based Maintenance (Rule-Based): Sensors monitor a threshold (e.g., “Alert if temperature > 80°C”).

- Pros: Monitors actual state.

- Cons: Rigid. It cannot predict complex failure modes or account for variable operating contexts (e.g., a machine naturally running hotter during a high-speed load).

- AI Predictive Maintenance (Data-Driven): Machine Learning algorithms analyze historical and real-time data to forecast when a failure will happen.

- Pros: Maximizes asset life, minimizes downtime, optimizes spare parts inventory.

- Cons: Requires data infrastructure, initial investment, and cultural change.

In practice, AI predictive maintenance transforms the maintenance department from a cost center (the people who fix broken things) into a value driver (the people who ensure maximum production capacity).

How It Works: The Data Journey

Implementing AI predictive maintenance is not about buying a “magic box” that predicts the future. It is about building a data pipeline. The journey of a predictive insight travels through four distinct layers.

1. The Physical Layer (Sensors and PLCs)

Every prediction starts with physical evidence. Smart factories utilize a vast array of sensors to capture the “vital signs” of machinery.

- Vibration Sensors: The gold standard for rotating machinery (motors, pumps, fans). They detect imbalances, misalignments, and bearing wear.

- Thermography/Temperature Sensors: Heat is often the first sign of friction, electrical resistance, or cooling failure.

- Acoustic/Ultrasonic Sensors: These can detect air leaks or early-stage metal fatigue that generates sound frequencies beyond human hearing.

- Power Consumption Meters: Spikes in voltage or amperage can indicate a motor working too hard due to a mechanical jam or degradation.

2. The Communication Layer (Edge and Cloud)

Data trapped in a machine is useless. It must be transported.

- Edge Computing: In modern setups, data is often processed locally on “edge gateways” attached to the machine. This allows for instant alerts (latency <10ms) without needing to send terabytes of raw vibration data to the cloud.

- Protocols: Standards like OPC UA and MQTT are the languages machines use to talk to IT systems, breaking down the silos between different equipment manufacturers.

3. The Analytical Layer (AI and Machine Learning)

This is where the raw data becomes intelligence.

- Anomaly Detection: The AI learns what “normal” looks like for a specific machine under specific loads. If the vibration pattern shifts slightly outside this learned norm, it flags an anomaly.

- Remaining Useful Life (RUL): Regression models estimate exactly how much time is left before a component fails. Instead of a generic alert, the system says, “Bearing B failures probable in 14 days.”

- Root Cause Analysis: Advanced classifiers can correlate the current anomaly with past failure signatures to suggest why the issue is happening (e.g., “85% probability of lubricant breakdown”).

4. The Action Layer (Dashboards and CMMS)

Insights must trigger action. A predictive alert should automatically generate a work order in the Computerized Maintenance Management System (CMMS), informing the technician what to inspect, where the machine is, and which tools they will likely need.

Key Technologies Driving Adoption

As of early 2026, several converging technologies have lowered the barrier to entry for AI predictive maintenance.

The Industrial Internet of Things (IIoT)

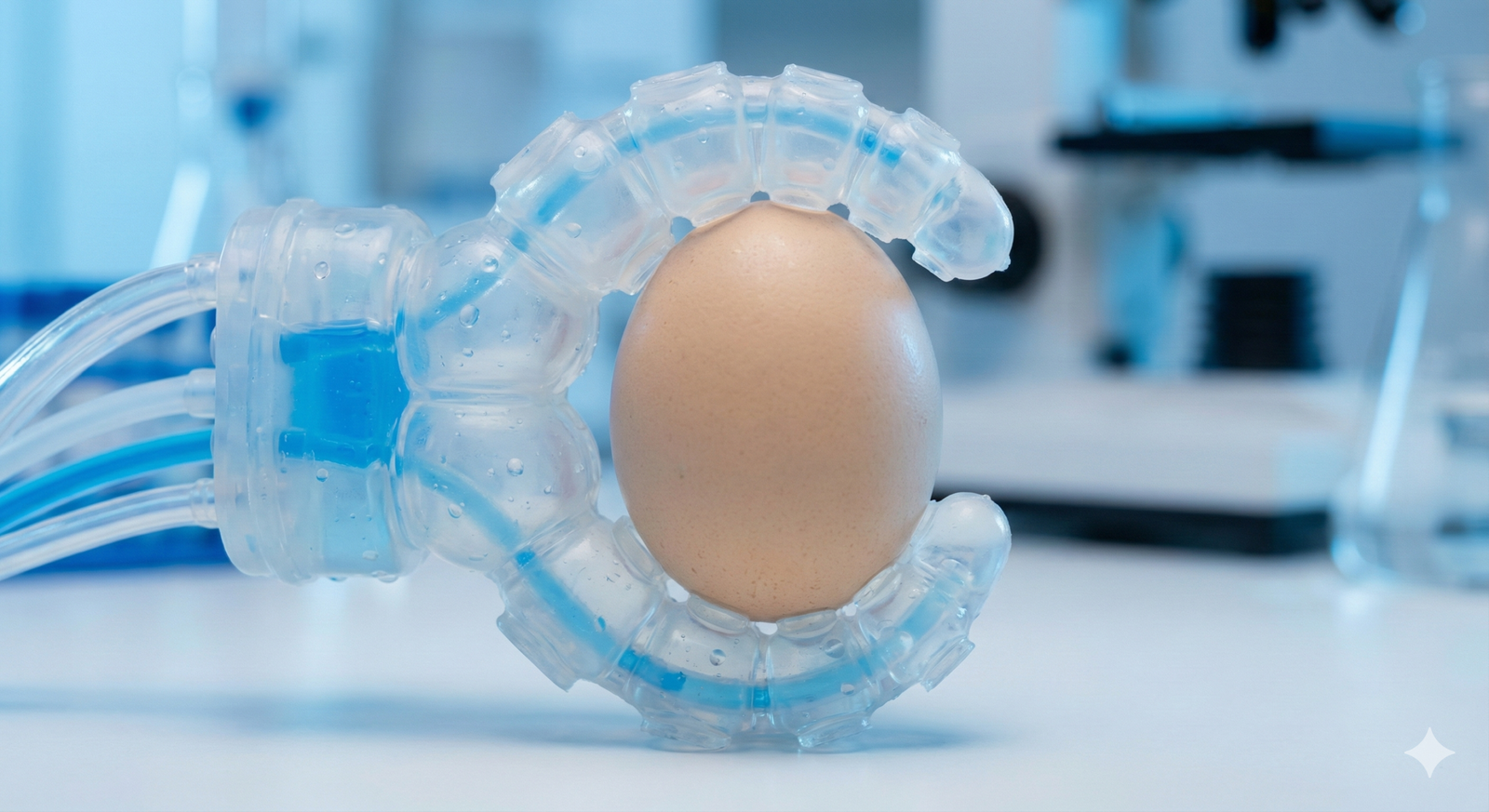

IIoT has commoditized data collection. Wireless, battery-powered vibration sensors can now be magnetically attached to legacy motors in minutes (“peel and stick” sensors), bypassing the need to rewire the entire factory. This allows for the digitalization of “brownfield” sites—older factories that were not originally built with connectivity in mind.

Edge AI

Historically, AI required massive cloud servers. Now, efficient “TinyML” models can run on small microcontrollers directly on the sensor. This reduces bandwidth costs and improves security, as sensitive operational data doesn’t always need to leave the factory premises.

Digital Twins

A Digital Twin is a virtual replica of a physical asset. By feeding real-time sensor data into the twin, engineers can run simulations. For example, they can ask, “If we run this conveyor at 120% speed for the next week to meet a deadline, how much life will we shave off the motor?” The AI predicts the wear and tear, allowing managers to make informed trade-offs between production speed and asset health.

Cloud Computing & Scalability

Platforms like AWS Industrial, Microsoft Azure IoT, and Google Cloud Manufacturing have built pre-trained models for common equipment (like pumps and compressors). This means factories don’t always need to hire a team of PhD data scientists to build models from scratch; they can tune pre-existing models to their specific equipment.

The Business Case: Why Adopt Now?

The argument for AI predictive maintenance is financial, operational, and sustainable.

1. ROI and Downtime Reduction

Unplanned downtime is the single biggest killer of manufacturing profitability. When a critical bottleneck machine fails, the entire line stops. Labor sits idle, materials may spoil, and shipping dates are missed.

- Impact: Industry data suggests PdM can reduce downtime by 30–50% and increase machine life by 20–40%.

- Example: In automotive manufacturing, a single minute of downtime can cost $20,000+. Avoiding just one hour of unplanned stoppage pays for the entire predictive system for a year.

2. Spare Parts Optimization

Without prediction, factories must hoard spare parts “just in case.” With prediction, parts can be ordered “just in time.” This frees up working capital that was previously tied up in inventory sitting on shelves gathering dust.

3. Safety and Compliance

Catastrophic machine failures are dangerous. A pipe bursting under pressure or a robotic arm seizing can injure workers. Predictive maintenance detects dangerous conditions (like pressure build-ups or thermal runaways) before they become safety incidents.

4. Sustainability and Energy Efficiency

A degrading machine is an inefficient machine. A motor with a worn bearing might consume 10–15% more electricity to do the same work. By maintaining optimal health, factories reduce their energy footprint and carbon emissions, aligning with ESG (Environmental, Social, and Governance) goals.

Step-by-Step Implementation Framework

Implementing AI predictive maintenance is a complex project that fails if treated solely as an IT upgrade. It is an operational transformation.

Phase 1: Assessment and Pilot Selection

Do not try to monitor every machine in the factory on day one.

- Asset Criticality Ranking: Rank your machines based on the cost of failure. Which machines are the bottlenecks? Which are hard to source parts for?

- The “Bad Actor” List: Identify the assets that fail most frequently.

- Pilot Scope: Choose 5–10 critical assets for a pilot program. Success here will prove the value to leadership.

Phase 2: Data Acquisition Strategy

Assess the data you have versus the data you need.

- Audit Existing Sensors: Can you tap into existing PLC data?

- Fill the Gaps: Install retrofit sensors where necessary. Wireless vibration and temperature sensors are usually the first addition.

- Connectivity: Ensure the factory floor Wi-Fi, LoRaWAN, or 5G network is robust enough to handle the data transmission.

Phase 3: Establishing the Baseline

AI needs to learn. Before it can predict failure, it must understand “normal.”

- Training Period: Run the machines with the sensors active for 2–4 weeks to gather baseline data.

- Historical Context: If you have logs of past failures (e.g., “Motor A failed on Jan 12th due to bearing seizure”), feed this into the model. This “labeled data” is incredibly valuable for Supervised Learning.

Phase 4: Model Deployment and Tuning

Deploy the AI models. Initially, the system will likely generate false positives (alerting when nothing is wrong).

- Feedback Loop: This is crucial. When the AI sends an alert, the maintenance technician must check the machine and report back to the system: “Yes, the bearing was loose” or “No, the machine was just running a new product type.”

- Refinement: The model uses this feedback to reduce false alarms and improve accuracy.

Phase 5: Workflow Integration

This is where most projects fail. An alert on a dashboard that nobody looks at is useless.

- Integration: Connect the AI platform to your CMMS (e.g., SAP, IBM Maximo, Fiix).

- Automation: When a “High Severity” alert occurs, a work order should be created automatically and assigned to a technician.

Phase 6: Scaling

Once the pilot shows ROI (e.g., “We saved $50k by catching that gearbox failure”), roll out the solution to Tier 2 and Tier 3 assets.

Common AI Algorithms Used

While managers don’t need to code, understanding the “flavor” of AI helps in vendor discussions.

1. Anomaly Detection (Unsupervised Learning)

This is the most common starting point. The algorithm looks at clusters of data points. If a new data point falls far outside the cluster of “normal operation,” it is flagged.

- Use Case: Detecting a foreign object in a textile loom or a sudden vibration spike in a fan.

- Why it’s popular: It doesn’t require a history of failures to work; it just needs to know what “good” looks like.

2. Regression Models (Supervised Learning)

These models predict a continuous value, specifically Remaining Useful Life (RUL).

- Use Case: Predicting that a brake pad has 400 cycles left before it becomes unsafe.

- Requirement: Requires a lot of historical data showing the degradation curve of the component.

3. Classification Models (Supervised Learning)

These models categorize the type of fault.

- Use Case: Distinguishing between an “inner race bearing fault” vs. an “outer race bearing fault” vs. a “lubrication issue.”

- Requirement: Needs highly detailed, labeled data from past failures.

Real-World Use Cases & Examples

Automotive Manufacturing: Robotic Welding Arms

In car manufacturing, robotic arms perform thousands of welds per day. If a joint seizes, the line stops.

- The AI Solution: Sensors monitor the torque and current draw of the robot’s servo motors.

- The Result: AI detects that the torque required to move “Joint 3” has increased by 5% over the last week. It predicts a gear failure in 72 hours. Maintenance lubricates the gear during a planned lunch break, preventing a 4-hour line stoppage.

Food and Beverage: Industrial Freezers

In frozen food processing, keeping temperature consistent is a regulatory safety requirement.

- The AI Solution: Models analyze the compressor’s vibration and the coolant pressure cycles.

- The Result: The system notices the compressor is cycling more frequently to maintain temperature—a sign of a slow coolant leak. The leak is fixed before the freezer fails, saving $100,000 worth of perishable inventory.

Oil and Gas: Remote Pumps

Offshore rigs use massive pumps to move crude oil. Sending a technician to inspect them is expensive and dangerous.

- The AI Solution: Digital Twins simulate the pump’s performance based on real-time flow data.

- The Result: The operator sees that Pump B is vibrating abnormally only when pumping at 80% capacity. They adjust the schedule to run it at 60% capacity until parts arrive, avoiding a catastrophic blowout.

Challenges and Pitfalls

Despite the promise, adoption is not without hurdles.

1. The Data Swamp

Factories generate terabytes of data, but much of it is “dirty”—missing timestamps, labeled incorrectly, or stuck in proprietary formats. Cleaning and structuring data usually takes 80% of the project time; the AI part takes only 20%.

2. The Silo Problem

Traditionally, the OT team (Operational Technology—the people running the machines) and the IT team (Information Technology—the people managing servers) did not talk. PdM requires them to collaborate closely. Bridging this cultural gap is often harder than the technical integration.

3. “Pilot Purgatory”

Many companies run a successful pilot but fail to scale because they didn’t plan for the infrastructure costs or the change management required to roll it out to 500 machines.

4. Skill Gaps

The manufacturing workforce is aging. Experienced reliability engineers who can diagnose a machine by touch are retiring. AI helps capture their knowledge, but there is a shortage of workers who understand both mechanical engineering and data interpretation.

The Role of Human Operators

A common fear is that AI will replace maintenance staff. In practice, the opposite is true: AI empowers maintenance staff.

AI is excellent at sifting through data, but it has no hands. It cannot replace a seal, tighten a bolt, or make a judgment call on whether to risk running a machine for one more hour.

The “Centaur” Approach: The most effective teams combine human intuition with AI insights. The AI acts as the “Check Engine Light” on steroids, pointing the human expert to exactly where the problem is. This eliminates the drudgery of routine inspections (walking around with a clipboard checking gauges) and frees up skilled technicians to focus on complex repairs and improvements.

Furthermore, the “human-in-the-loop” is essential for training the AI. When the AI says, “I think this is a bearing fault,” and the human confirms it, the AI gets smarter.

Future Trends

As of 2026, the horizon for predictive maintenance is expanding rapidly.

Generative AI for Maintenance

Large Language Models (LLMs) are being trained on technical manuals and historical maintenance logs. A technician can now type into a chat interface: “Machine X is vibrating at 40Hz and overheating. What should I check?” The AI can instantly synthesize a troubleshooting guide based on the OEM manual and the factory’s history of similar issues.

Self-Healing Machines

We are seeing the early stages of autonomous maintenance, where software can automatically adjust machine parameters (like slowing down a motor or changing a PID loop) to compensate for wear and tear, effectively “healing” the process temporarily until a human can fix the hardware.

Energy-Centric Maintenance

With rising energy costs, maintenance is shifting from purely “reliability-focused” to “efficiency-focused.” AI will prioritize repairs not just based on failure risk, but on which degrading assets are wasting the most electricity.

Conclusion

AI predictive maintenance is no longer an experimental technology; it is a fundamental pillar of the modern smart factory. By transitioning from reactive fire-fighting to proactive strategic planning, manufacturers can unlock massive efficiencies, improve worker safety, and boost their bottom line.

However, technology is only half the equation. The most successful implementations are those that treat PdM as a business transformation—investing as much in training their people and cleaning their data as they do in the AI algorithms.

The factories of the future will not be silent; they will be communicative. They will tell us what they need, when they need it, and how to keep them running at peak performance. For manufacturers willing to listen, the rewards are substantial.

Next Steps for Leaders

- Identify your pain points: Look at your downtime logs for the last 12 months. Which 3 machines caused the most lost production hours?

- Start small: Do not try to “boil the ocean.” Launch a 90-day pilot on those 3 critical machines using retrofit sensors.

- Audit your data: check if your current machines can export data via OPC UA or MQTT. If not, budget for IoT gateways.

FAQs

What is the difference between Predictive Maintenance and Prescriptive Maintenance?

Predictive maintenance tells you when a failure will happen (e.g., “The bearing will fail in 2 days”). Prescriptive maintenance goes a step further and tells you what to do about it (e.g., “Reduce speed by 10% immediately and schedule a replacement for Tuesday”). Prescriptive uses AI to simulate outcomes and recommend the best course of action.

How much historical data do I need to start AI predictive maintenance?

For anomaly detection (identifying weird behavior), you often only need 2–4 weeks of “healthy” baseline data. However, for precise failure prediction (RUL) or root cause analysis, you typically need 6–12 months of historical data that includes examples of past failures so the model can learn what a “breakdown” looks like.

Can predictive maintenance work on old (legacy) machines?

Yes. In fact, legacy machines often yield the highest ROI. You do not need to replace the machine; you simply attach external IoT sensors (vibration, acoustic, temperature) to the motor or housing. These “brownfield” retrofits allow 40-year-old lathes to communicate just like brand-new smart equipment.

What are the most common sensors used for predictive maintenance?

Vibration sensors (accelerometers) are the most common because they are effective for motors, pumps, fans, and compressors. Temperature sensors are second. Acoustic/ultrasonic sensors are growing in popularity for leak detection, and oil quality sensors are used for hydraulic systems.

Is AI predictive maintenance expensive?

The cost has dropped significantly. While enterprise-wide rollouts can cost hundreds of thousands of dollars, pilot programs using “Maintenance-as-a-Service” (MaaS) models can start for a few thousand dollars per month. The key is to calculate the Cost of Downtime—if avoiding one breakdown saves $50k, the system pays for itself quickly.

Does predictive maintenance require cloud connectivity?

Not always. While the cloud is great for training complex models and aggregating data across multiple factories, the actual monitoring is increasingly done at the “Edge” (on the machine itself). This ensures data security and allows the system to work even if the internet connection goes down.

Why do predictive maintenance projects fail?

The most common reasons for failure are poor data quality (garbage in, garbage out), lack of clear business goals (measuring technology instead of value), and cultural resistance from the maintenance team who may feel threatened by the new technology or find it difficult to use.

What is the accuracy of predictive maintenance models?

Accuracy varies by application and data quality. Well-tuned vibration models can often predict mechanical failures with >90% accuracy 48 hours in advance. However, models are probabilistic, not prophetic—they give a likelihood of failure, not a guarantee.

Can AI predict every type of machine failure?

No. AI is excellent at predicting degradation (wear and tear, fatigue, gradual loosening). It is less effective at predicting random, instantaneous failures caused by external accidents, such as a forklift hitting a machine or a sudden power surge, unless those events leave a precursor data trail.

How does 5G affect predictive maintenance?

5G allows for massive machine-type communications (mMTC). It enables factories to connect thousands of wireless sensors with ultra-low latency and high reliability without the cabling costs of wired connections or the interference issues of Wi-Fi in metal-heavy environments.

References

- Deloitte Insights. (2024). Predictive Maintenance and the Smart Factory: Using AI to reduce downtime. Deloitte University Press. https://www2.deloitte.com

- McKinsey & Company. (2023). Smart Manufacturing: Capturing value from the digital revolution. McKinsey Operations Practice. https://www.mckinsey.com

- NIST (National Institute of Standards and Technology). (2025). Guide to Industrial Wireless Systems and Edge Computing Standards. U.S. Department of Commerce. https://www.nist.gov

- International Society of Automation (ISA). (2024). ISA-95 Enterprise-Control System Integration Standards. ISA Standards. https://www.isa.org

- Siemens Industrial. (2025). Whitepaper: The Convergence of IT and OT in Predictive Maintenance. Siemens Digital Industries. https://www.siemens.com

- GE Vernova. (2024). Asset Performance Management (APM) Best Practices Guide. GE Digital. https://www.gevernova.com

- PwC. (2025). Digital Factory 2030: The Future of Manufacturing. PwC Global Manufacturing Review. https://www.pwc.com

- IEEE Xplore. (2024). Survey on Deep Learning for Industrial Predictive Maintenance. IEEE Transactions on Industrial Informatics. https://ieeexplore.ieee.org

- Bosch Rexroth. (2023). Connected Hydraulics and the Future of IoT. Bosch Global. https://www.boschrexroth.com

- Emerson Automation Solutions. (2024). Top Quartile Reliability: The Business Case for PdM. Emerson. https://www.emerson.com