In the volatility of the modern global economy, the supply chain has graduated from a back-office operational function to a boardroom strategic priority. The era of static spreadsheets and historical averages is over. Today, AI for supply chain optimization is the critical differentiator between businesses that merely survive disruptions and those that thrive because of them.

As of January 2026, we are witnessing a fundamental shift in logistics and procurement. The old “Just-in-Time” models, which prioritized leanness above all else, often fractured under the pressure of global events. The new paradigm is “Just-in-Case”—a model built on resilience, visibility, and agility, all powered by artificial intelligence.

This guide explores how AI is reshaping the movement of goods, from predictive demand forecasting to autonomous last-mile delivery, and how organizations are balancing the need for efficiency (optimization) with the capability to withstand shock (resilience).

Key Takeaways

- Beyond Efficiency: AI is no longer just about cutting costs; it is the primary tool for building resilience against global disruptions.

- Predictive Power: Machine learning enables companies to foresee demand spikes and supply shortages weeks or months in advance, rather than reacting after the fact.

- The Rise of Digital Twins: Virtual replicas of supply chains allow businesses to simulate “what-if” scenarios, testing their readiness for crises without real-world risk.

- Generative AI in Procurement: New AI tools are automating complex contract negotiations and supplier communication, freeing humans for strategic relationship building.

- Sustainability: AI optimization is a key driver in reducing carbon footprints by minimizing waste and optimizing fuel consumption.

Who This Is For (And Who It Isn’t)

This guide is written for supply chain managers, logistics directors, operations executives, and digital transformation leaders who are looking to modernize their infrastructure. It is also suitable for students and business analysts seeking a comprehensive overview of the current technology landscape.

This is not a technical documentation manual for coding specific machine learning algorithms, nor is it a basic glossary of terms. It focuses on strategic application, functional benefits, and implementation realities.

Understanding the Role of AI in Modern Supply Chains

To understand the impact of AI, we must first recognize the complexity of the modern supply chain. A single product often involves dozens of suppliers across multiple continents, subject to weather patterns, geopolitical shifts, and labor dynamics. Managing this web with human intuition alone is impossible.

From Reactive to Proactive

Traditionally, supply chain management was reactive. A shipment was delayed, so a manager called the customer to apologize. Material costs went up, so procurement negotiated harder for the next quarter.

AI shifts this dynamic to proactive management. By analyzing vast datasets—weather reports, news feeds, port congestion data, and historical sales—AI systems can predict a delay before the ship even leaves the port. This allows managers to reroute shipments or source materials from an alternative supplier before the disruption impacts the production line. This shift from “fixing problems” to “preventing problems” is the core value proposition of AI in this sector.

The Core Technologies

When we talk about “AI” in supply chains, we are usually referring to a stack of specific technologies:

- Machine Learning (ML): Algorithms that learn from historical data to identify patterns and make predictions (e.g., forecasting demand).

- Natural Language Processing (NLP): Used to read contracts, process emails from suppliers, and analyze news sentiment for risk alerts.

- Computer Vision: Cameras in warehouses and shipping yards that can identify damaged goods, track inventory levels, or ensure safety compliance.

- Robotics and Automation: Physical hardware controlled by AI, such as autonomous mobile robots (AMRs) in warehouses or drones for inventory checks.

How AI Drives Supply Chain Optimization

Optimization is about doing more with less: less time, less money, and fewer resources. AI achieves this by removing the guesswork from decision-making.

Precision Demand Forecasting

Demand forecasting is the holy grail of inventory management. Traditional methods often relied on Year-Over-Year (YoY) comparisons—assuming that what sold last January will sell this January. However, this approach fails to account for new trends, economic downturns, or viral social media moments.

AI-driven demand forecasting ingests a much wider array of signals. It looks at:

- Internal data: Sales history, marketing promotions, pricing changes.

- External data: Weather forecasts, competitor pricing, economic indicators, and even social media sentiment.

By synthesizing this data, predictive analytics in logistics can forecast demand with significantly higher accuracy. This reduces the “bullwhip effect,” where small fluctuations in consumer demand cause massive over-corrections further up the supply chain.

Inventory Management and Dynamic Stocking

Once demand is forecasted, inventory management AI takes over to ensure the right products are in the right place. Overstocking leads to high storage costs and potential waste (especially for perishables), while understocking leads to lost revenue and damaged customer loyalty.

AI systems facilitate “dynamic stocking.” Instead of static reorder points (e.g., “order more when we have 50 units left”), the system adjusts the reorder point based on the predicted speed of sales and lead times. If a supplier is predicted to be slow due to a holiday in their country, the AI orders earlier. If sales for a product are trending down, the AI delays the order to prevent dead stock.

Logistics and Route Optimization

Transportation often accounts for the largest portion of supply chain costs. Route optimization algorithms go far beyond simple GPS navigation. They solve complex “Traveling Salesman” problems involving hundreds of delivery points, varying vehicle capacities, driver shift constraints, and traffic windows.

In practice, this looks like a delivery fleet that dynamically re-routes in real-time. If a recipient cancels an order or a traffic accident blocks a highway, the AI instantly recalculates the most efficient sequence for the remaining deliveries. This not only saves fuel and time but also improves the customer experience by providing accurate, dynamic arrival times.

Smart Warehousing and Automation

Smart warehousing is perhaps the most visible application of AI. Warehouses are transforming from static storage facilities into active, intelligent hubs.

- autonomous mobile robots (AMRs): These robots move goods from shelves to packing stations. Unlike old automated guided vehicles (AGVs) that followed magnetic strips, AI-powered AMRs use LiDAR and cameras to navigate around obstacles and people dynamically.

- Bin-picking robots: Using computer vision, robotic arms can now identify and pick disparate items from a bin, a task that was previously easy for humans but incredibly difficult for machines.

- Slotting optimization: AI analyzes which items are bought together and places them near each other in the warehouse to reduce travel time for pickers.

Building Resilience with Artificial Intelligence

While optimization focuses on speed and cost, supply chain resilience focuses on survival and adaptability. In a world of frequent “black swan” events—pandemics, canal blockages, trade wars—resilience is arguably more valuable than pure efficiency.

Supply Chain Visibility (End-to-End)

You cannot fix what you cannot see. A major challenge in traditional supply chains is the “tier 2+ blind spot.” Companies often know their direct suppliers (Tier 1) well, but have zero visibility into who supplies their suppliers (Tier 2 and beyond). If a Tier 2 factory burns down, the company might not know until their Tier 1 supplier fails to deliver weeks later.

AI platforms scrape news, financial reports, and shipping data to map out these multi-tier networks. They provide supply chain visibility that alerts managers to risks deep in the network. If an earthquake hits a region where a critical sub-component is manufactured, the AI flags every product line that relies on that component, allowing the company to activate backup sourcing immediately.

Supplier Risk Management and Scoring

Evaluating suppliers has traditionally been a manual, periodic process involving audits and spreadsheets. Supplier risk management tools powered by AI monitor suppliers 24/7. They analyze:

- Financial health: Predicting bankruptcy risk based on payment patterns and public financial data.

- Geopolitical risk: assessing the stability of the region where the supplier operates.

- Sustainability and compliance: Scanning for news regarding labor violations or environmental fines.

This continuous scoring allows procurement teams to diversify their supplier base proactively rather than scrambling when a key supplier goes under.

Scenario Planning and Digital Twins

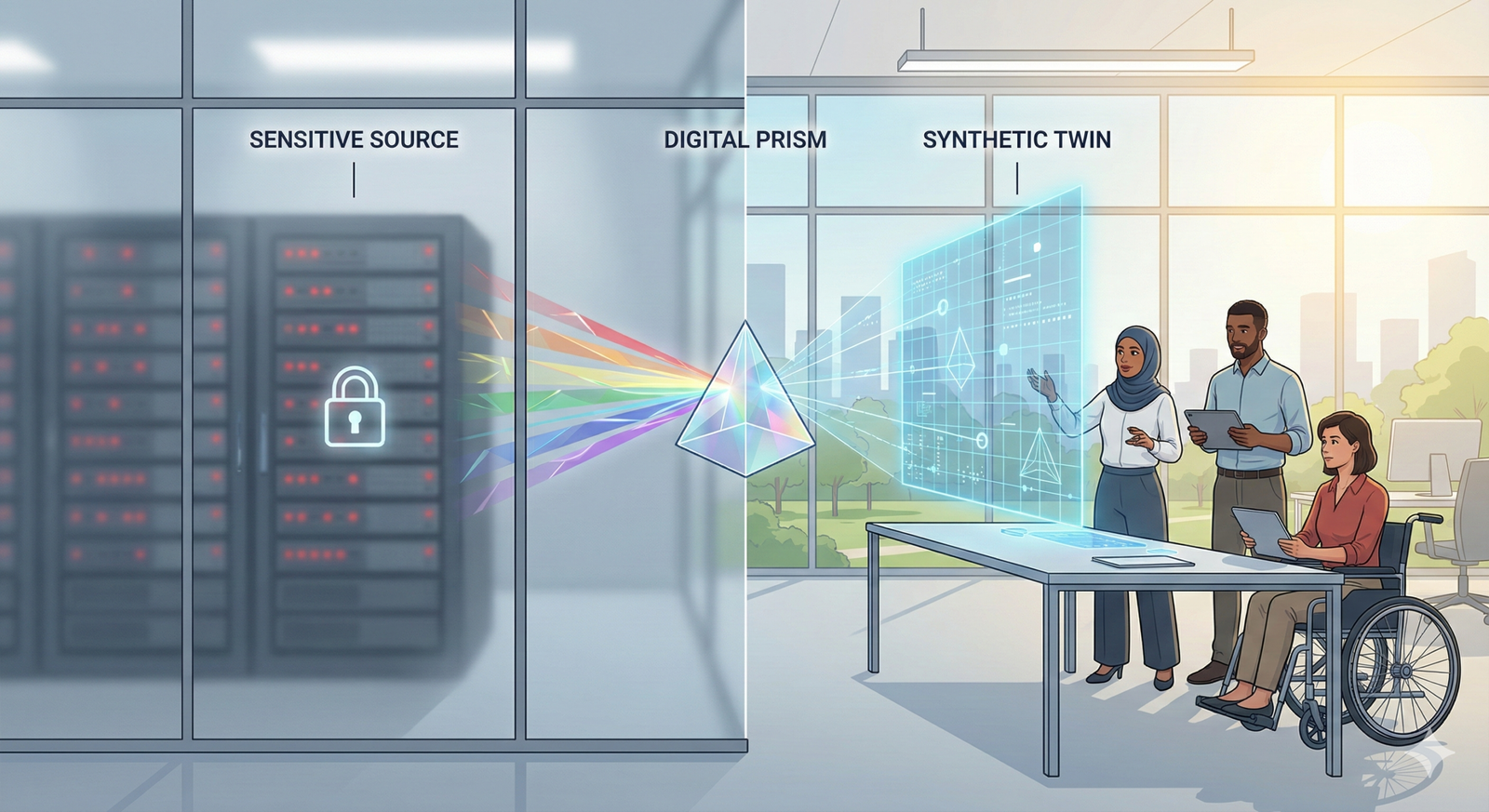

One of the most powerful tools for resilience is the digital twin. A digital twin is a virtual replica of the entire physical supply chain—factories, warehouses, transit routes, and inventory levels.

Using this twin, companies can run simulations. They can ask, “What happens to our revenue if the Port of Los Angeles shuts down for two weeks?” or “What if the price of oil doubles?” The AI simulates the ripple effects across the network, highlighting bottlenecks and vulnerabilities. This allows companies to build contingency plans based on data, not intuition.

Generative AI: The New Frontier in Logistics

As of 2026, Generative AI (GenAI) has moved beyond text generation into functional utility within supply chains. While predictive AI deals with numbers and forecasts, GenAI handles unstructured data and creation.

Automating Procurement and Contracts

Procurement involves reading and writing thousands of pages of contracts, RFPs (Request for Proposals), and compliance documents. Generative AI for procurement can draft RFPs based on simple prompts, compare incoming supplier bids against historical benchmarks, and summarize complex contract terms for legal review.

For example, a procurement officer can ask a GenAI agent, “Draft a contract for a new silicon supplier that includes our standard sustainability clauses and a penalty for late delivery exceeding 3 days.” The AI produces a near-final draft in seconds, ensuring consistency and saving hours of legal drafting time.

Enhancing Supplier Communication

Communicating with thousands of suppliers in different languages is a logistical nightmare. GenAI tools serve as translation and negotiation intermediaries. They can draft emails in the supplier’s native language, query suppliers for missing documentation, and even conduct low-level price negotiations within pre-set parameters approved by human managers.

Synthetic Data for Training Models

One barrier to AI adoption is a lack of clean historical data. GenAI can create synthetic data—artificial data that mimics the statistical properties of real-world data—to train supply chain models. This is particularly useful for training models to recognize rare events (like a massive hurricane) that don’t happen often enough to generate sufficient real-world training data.

Sustainability and Ethical Supply Chains

Sustainability in supply chain operations is no longer optional; it is a regulatory requirement and a consumer demand. AI is the engine that makes “green logistics” feasible.

Reducing Carbon Footprint via AI

Optimization is inherently sustainable. Every mile cut from a delivery route reduces emissions. Every container packed more efficiently (using volumetric optimization algorithms) means fewer trips.

- Load Optimization: AI analyzes 3D dimensions of packages to determine the optimal way to stack pallets in a truck, minimizing “shipping air.”

- Modal Switching: AI systems can suggest intermodal shifts—for example, recommending rail instead of air freight for a specific leg of the journey where time sensitivity allows, drastically reducing the carbon footprint.

Ethical Sourcing and Traceability

Consumers want to know that their products were not made with forced labor or illegal materials. AI combines with blockchain technology to create immutable records of a product’s journey. Computer vision can analyze satellite imagery to verify that raw materials (like timber or palm oil) are not coming from protected deforestation zones, ensuring ethical compliance.

Key Use Cases and Real-World Applications

To illustrate the power of these technologies, we look at how different sectors apply them.

Manufacturing: Predictive Maintenance

In manufacturing supply chains, a broken machine on the assembly line stops the entire flow. AI sensors monitor equipment vibration, temperature, and sound to predict failure before it happens. This predictive maintenance ensures that spare parts are ordered and repairs are scheduled during planned downtime, preventing unplanned supply interruptions.

Retail: Personalized Fulfillment

Retail giants use AI to predict not just what will sell, but where. By positioning inventory in micro-fulfillment centers closer to predicted buyers, they enable same-day delivery. If an AI predicts a heatwave in Chicago, it preemptively moves air conditioners to warehouses in Illinois, reducing last-mile delivery distances.

Cold Chain Logistics: Monitoring Quality

For pharmaceuticals and fresh food, temperature control is vital. AI sensors in shipping containers monitor temperature and humidity in real-time. If a container’s cooling unit begins to fail, the AI alerts the logistics provider immediately, allowing them to intervene or prioritize that shipment to save the cargo.

Challenges and Barriers to Adoption

Despite the benefits, implementing AI in supply chains is fraught with difficulties.

Data Quality and Silos

AI is only as good as the data it feeds on. In many organizations, data is trapped in silos—procurement uses one software, logistics uses another, and sales uses a third. These systems often don’t talk to each other. Cleaning “dirty data” (duplicate records, missing fields, incompatible formats) is often 80% of the work in an AI project. Without a unified data strategy, AI models will hallucinate or provide inaccurate forecasts.

Cost of Implementation vs. ROI

Building logistics automation requires significant upfront investment in software, sensors, and potentially robotics. Smaller companies often struggle to justify the CapEx (Capital Expenditure). Calculating ROI can be tricky, as the value of “resilience” (avoiding a crisis) is invisible until a crisis actually occurs.

The Talent Gap and Change Management

There is a shortage of professionals who understand both supply chain dynamics and data science. Furthermore, existing employees may fear that logistics automation puts their jobs at risk. Effective change management is required to upskill workers and show them how AI acts as a “co-pilot” rather than a replacement.

Security and Compliance Risks

Connecting a supply chain to the internet increases the attack surface for cybercriminals. If a hacker compromises an AI system, they could potentially reroute shipments or manipulate inventory data. Ensuring cybersecurity protocols around these AI agents is a critical compliance requirement.

Implementation Strategy: A Phased Approach

For organizations looking to integrate AI, a “big bang” approach rarely works. A phased adoption strategy is recommended.

- Phase 1: Assessing Maturity and Unifying Data. Before buying AI tools, audit your current data landscape. Break down silos and create a “single source of truth” data lake.

- Phase 2: Pilot Projects. Start with low-risk, high-reward areas. Route optimization or basic demand forecasting for a single product line are excellent starting points. These projects prove value quickly.

- Phase 3: Scaling Up. Once pilots are successful, expand to inventory management AI and broader forecasting. Begin integrating supplier data.

- Phase 4: Ecosystem Integration. The final stage involves full digital twins, end-to-end visibility, and automated decision-making where the AI doesn’t just recommend actions but executes them (e.g., automatically reordering stock).

Future Trends to Watch (2026 and Beyond)

As we look toward the latter half of the decade, two trends stand out:

Autonomous Fleets

While fully autonomous trucks are still navigating regulatory hurdles, semi-autonomous convoys (platooning) are becoming reality on highways. In closed environments like ports and mines, fully autonomous vehicles are already standard. We expect last-mile delivery AI (drones and sidewalk robots) to see expanded regulation frameworks allowing for broader urban use.

Blockchain and AI Integration

Blockchain provides the trust, and AI provides the intelligence. We will see more platforms where AI validates the quality of goods and instantly records the certification on a blockchain, executing “smart contracts” that pay suppliers the moment the goods are verified, dramatically speeding up cash flow in the supply chain.

Related Topics to Explore

- The Internet of Things (IoT) in Logistics: How sensors provide the raw data that feeds AI brains.

- Green Logistics Strategies: Deep dives into circular supply chains and waste reduction.

- Cybersecurity in Operational Technology (OT): Protecting the physical hardware of the supply chain.

- Cloud ERP Systems: The backbone infrastructure required to run modern AI tools.

- Robotic Process Automation (RPA): The bridge between legacy systems and modern AI.

Conclusion

The integration of AI for supply chain optimization represents a definitive break from the past. We have moved from a world where supply chains were linear, opaque, and reactive to one where they are networked, transparent, and predictive.

For business leaders, the message is clear: resilience is not a luxury; it is an insurance policy against an unpredictable world. By leveraging machine learning in logistics, digital twins, and predictive analytics, organizations can build supply chains that don’t just withstand stress but improve because of it.

The journey to an AI-driven supply chain does not happen overnight. It requires clean data, strategic investment, and a culture willing to trust algorithms alongside human intuition. However, the cost of inaction—being left with a fragile, blind supply chain in a volatile market—is far higher.

Next Steps: Begin by auditing your data visibility. Can you see your inventory in real-time? If not, prioritize a data unification project before investing in advanced AI models.

FAQs

1. What is the difference between supply chain digitization and AI optimization? Digitization is the process of converting analog information (paper records) into digital formats. AI optimization goes a step further by using that digital data to make decisions, predict outcomes, and improve efficiency automatically. Digitization is the prerequisite; AI is the application.

2. How does AI help with supply chain sustainability? AI helps sustainability by optimizing routes to reduce fuel consumption, predicting demand to minimize waste and overproduction, and monitoring suppliers to ensure they adhere to environmental standards. It makes the supply chain leaner and more transparent.

3. Will AI replace human supply chain managers? Unlikely. AI is intended to replace repetitive tasks (data entry, tracking, basic forecasting) and augment decision-making. Humans are still required for strategic relationships, negotiation, crisis management, and handling edge cases that the AI has not encountered before.

4. What is a “Digital Twin” in supply chain? A digital twin is a virtual software replica of the physical supply chain. It uses real-time data to mirror the actual state of warehouses, transit, and inventory. Managers use it to run simulations and stress tests to see how the supply chain would perform under different conditions.

5. Is AI too expensive for small to mid-sized businesses (SMBs)? Not anymore. While building custom AI models is expensive, many modern SaaS (Software as a Service) supply chain platforms have AI features embedded in them (like demand forecasting or route planning) at a subscription cost accessible to SMBs.

6. How accurate is AI demand forecasting? While no forecast is 100% accurate, AI models typically outperform traditional methods by 15-20% or more because they can analyze non-linear data (like weather or social trends) that simple spreadsheets cannot. Accuracy improves over time as the model “learns” from more data.

7. What data is needed to implement AI in supply chain? You need historical sales data, inventory levels, lead times, supplier performance data, and logistics costs. For advanced models, you also need external data sources like weather, economic indicators, and competitor activity.

8. What are the security risks of AI in supply chain? The main risks involve data privacy (leaking sensitive supplier or customer data) and data poisoning (where bad data is fed to the AI to skew its decisions). There is also the risk of cyberattacks on the connected IoT devices feeding data to the AI.

9. How does Generative AI differ from traditional AI in logistics? Traditional AI (predictive AI) focuses on analyzing numbers to predict future numbers (e.g., forecasting sales). Generative AI creates new content—such as drafting contracts, writing emails to suppliers, or generating synthetic data for training—based on prompts.

10. What is the “Bullwhip Effect” and how does AI solve it? The Bullwhip Effect is a phenomenon where small fluctuations in retail demand cause progressively larger fluctuations in demand at the wholesale, distributor, and manufacturer levels. AI solves this by sharing real-time consumer data across the entire chain, ensuring everyone is reacting to the actual demand, not just the orders of the link below them.

References

- National Institute of Standards and Technology (NIST). (2023). Artificial Intelligence Risk Management Framework (AI RMF 1.0). https://www.nist.gov/itl/ai-risk-management-framework

- IBM Institute for Business Value. (2024). The Resilient Supply Chain: Built for the Future. https://www.ibm.com/thought-leadership/institute-business-value

- McKinsey & Company. (2024). Supply Chain 4.0 – the Next-Generation Digital Supply Chain. https://www.mckinsey.com/capabilities/operations/our-insights

- Council of Supply Chain Management Professionals (CSCMP). (2025). State of Logistics Report 2025. https://cscmp.org

- Harvard Business Review. (2023). How AI Is Helping Companies Redesign Their Supply Chains. https://hbr.org

- Association for Supply Chain Management (ASCM). (2024). Supply Chain Sustainability Standards. https://www.ascm.org

- Oracle. (2025). Oracle Supply Chain Management (SCM) & Manufacturing Documentation. https://docs.oracle.com/en/applications/supply-chain-management

- World Economic Forum. (2024). Unlocking Value in Manufacturing through Data Sharing. https://www.weforum.org